Description

Applications and Advantages

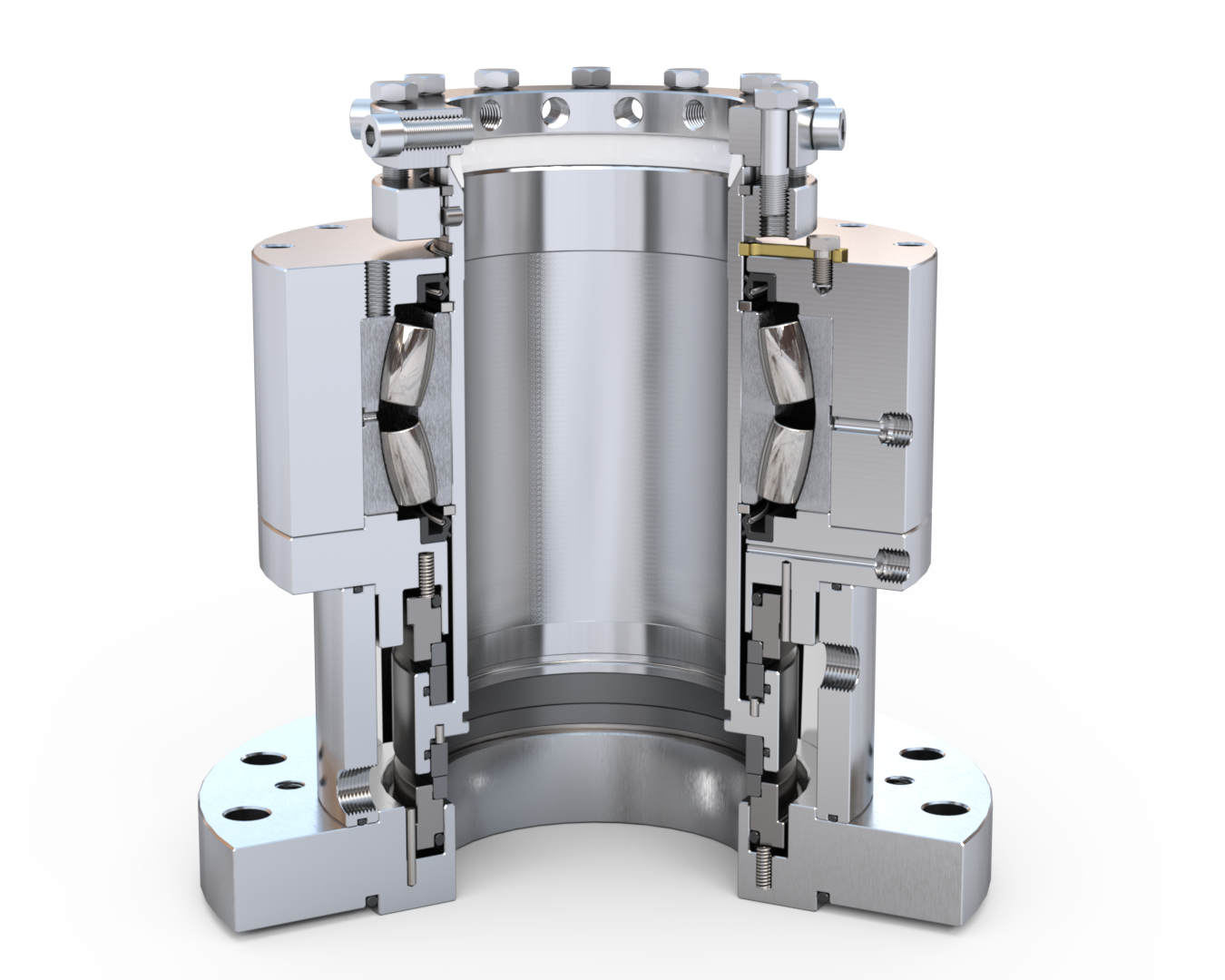

The MB1-DGS model by Orbit is engineered for cryogenic applications and excels in handling industrial gases in their liquid forms. With an innovative metallic bellow design that eliminates the need for dynamic O-rings, it ensures safety, reliability, and top-notch performance in cryogenic environments.

Whether it’s safeguarding pumps, compressors, or other cryogenic equipment, the DGS1 surpasses industry standards in:

- Efficiency: Reduces power loss with non-contacting seal faces.

- Longevity: Minimizes wear for extended operational life.

- Safety: Adheres to liquid oxygen (LOX) safety standards.

Operating Parameters

- Shaft Diameter: 18–150 mm

- Pressure: Up to 40 Bars

- Temperature: -196°C to Ambient

- Speed: Up to 40 m/s

Material Selection

The DGS1 is constructed with premium materials to withstand extreme operating conditions:

- Seal Faces: Carbon, Silicon Carbide (Sic), Tungsten Carbide (TC), and Suc.

- Secondary Seals: FFKM, FKM, PTFE, and HNBR.

- Metal Components: SS-316, Hastelloy C, and Inconel-718.

Applications

Orbit’s DGS1 is perfectly suited for sealing pumps operating with:

- Liquid Oxygen (LOX)

- Liquid Nitrogen (LIN)

- Liquid Argon (LAR)

Unique Features

- Compact and Easy Installation: Designed for minimal axial and radial space.

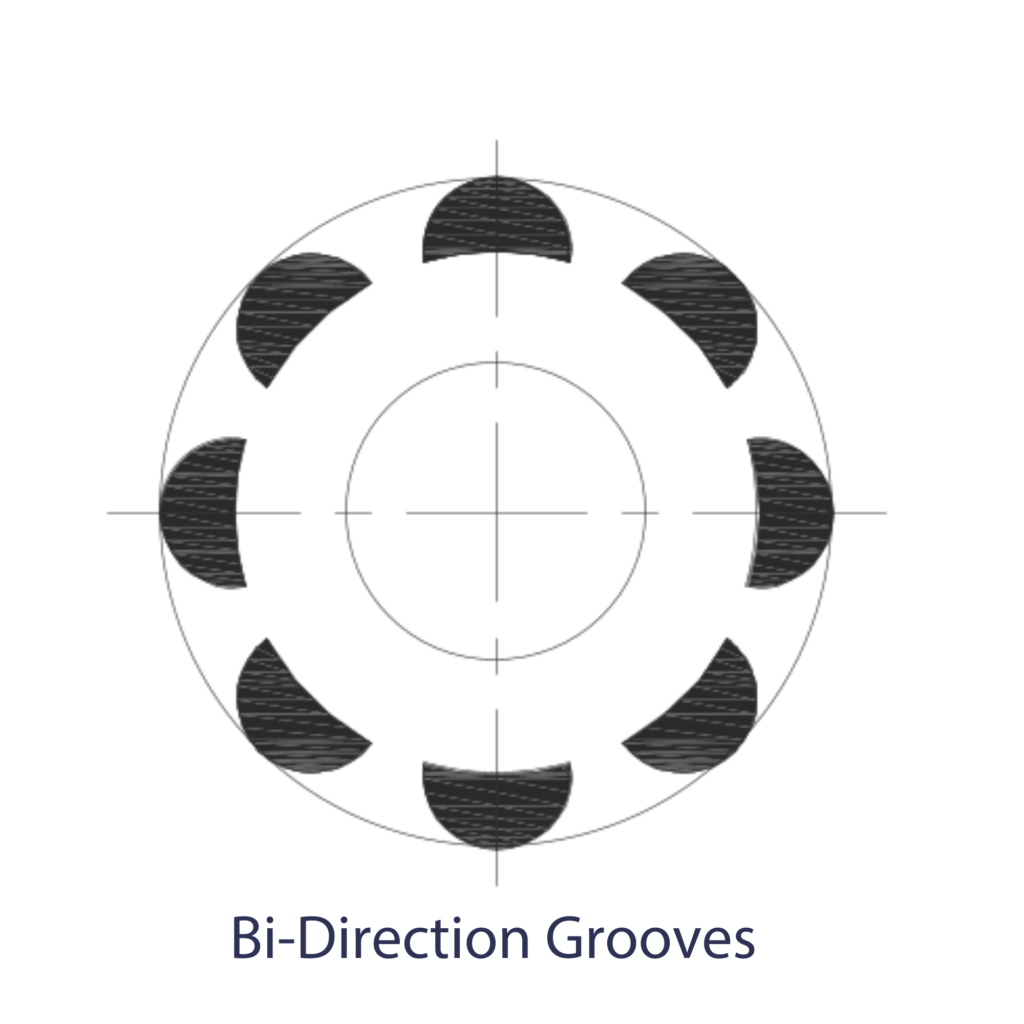

- Non-Contacting Seal Faces: Ensures no friction between faces for prolonged durability.

- Rugged Metallic Bellow Design: Prevents shaft/sleeve fretting and accommodates high RPMs.

- Minimum Parts: Simplifies installation and reduces downtime.

- Safety Standards: Complies with LOX safety protocols.

Boiling Points for Cryogenic Fluids

| Fluid | °C | °F |

|---|---|---|

| Oxygen | -183 | -297 |

| Nitrogen | -196 | -320 |

| Argon | -186 | -303 |

Industries Served

- Biofuels: Ensure efficient processing and storage of biofuels with Orbit’s robust sealing solutions.

- Chemical: Ideal for hazardous and reactive environments, ensuring leak-proof operations.

- Food & Beverage: Maintain purity and comply with stringent safety standards in food-grade applications.

- Oil & Gas: Withstand high pressures and extreme conditions in oil and gas operations.

- Power Generation: Enhance the reliability of pumps in critical power-generation setups.

- Petrochemicals: Handle aggressive chemicals and gases in petrochemical plants.

- Pharmaceutical: Ensure cleanliness and integrity in pharmaceutical production.

Seal Diagram

| Part # | Components | Material |

|---|---|---|

| 101 | Rotor | Tungsten Carbide |

| 102 | Seal Ring Stator | Carbon Graphite |

| 103 | Shims | Cu Alloy |

| 104 | O Ring | 3145 |

| 105 | Bellow Assy | Alloy-718 |

| 106 | Centering Ring | SS-316L |

| 107 | Gland Ring | SS-316L |

| 108 | Anti Spark Sleeve | Cu-Alloy |

Why Choose Orbit’s Single DGS?

At Orbit Fluid Solution LLP, our DGS1 combines innovation, precision, and unmatched reliability to provide your operations with the best-in-class sealing solutions. Trusted globally, we are committed to delivering products that enhance efficiency and drive sustainability across industries.

Get in touch with our experts to find the perfect sealing solution for your needs.