Description

Key Features of CR-DGS:

- Non-Contact Design

- Minimizes friction and wear for prolonged equipment life.

- Reduces maintenance requirements and operational downtime.

- Metallic Bellows Construction

- Eliminates the need for dynamic O-rings, ensuring reliability and safety.

- Suitable for high-speed applications and eliminates shaft/sleeve fretting.

- Compact and Easy Installation

- Requires minimal axial and radial space.

- Designed for quick assembly and disassembly.

- Rugged and Reliable Performance

- Engineered for high RPM operations.

- Meets Liquid Oxygen (LOX) Safety Standards for critical cryogenic processes.

Technical Specifications:

| Operating Parameters | Values |

|---|---|

| Shaft Diameter | 18 to 150 mm |

| Pressure | Up to 40 Bars |

| Temperature | -196°C to Ambient |

| Speed | Up to 40 m/s |

Materials:

| Component | Material Options |

|---|---|

| Seal Faces | Carbon, SiC, TC, PTFE-Composite |

| Secondary Seals | FFKM, FKM, PTFE, HNBR |

| Metal Components | SS-316, Hastelloy-C, Inconel-718 |

Applications:

The CR-DGS is designed for use with a wide range of cryogenic fluids, including:

- Liquid Oxygen (LOX)

- Liquid Nitrogen (LIN)

- Liquid Argon (LAR)

Boiling Points of Cryogenic Fluids:

| Fluid | Boiling Point (°C) | Boiling Point (°F) |

|---|---|---|

| Oxygen | -183 | -297 |

| Nitrogen | -196 | -320 |

| Argon | -186 | -303 |

Industries Served:

- Biofuels: Reliable sealing for high-performance biogas and biofuel production systems.

- Chemical: Ensures safety and efficiency in chemical processing and storage.

- Food & Beverage: Maintains hygienic and efficient handling of cryogenic fluids.

- Oil & Gas: Handles extreme operating conditions in the energy sector.

- Power Generation: Supports efficient cooling and cryogenic power systems.

- Petrochemicals: Resistant to aggressive chemicals, ensuring safe operations.

- Pharmaceutical: Guarantees precision sealing for contamination-free processes.

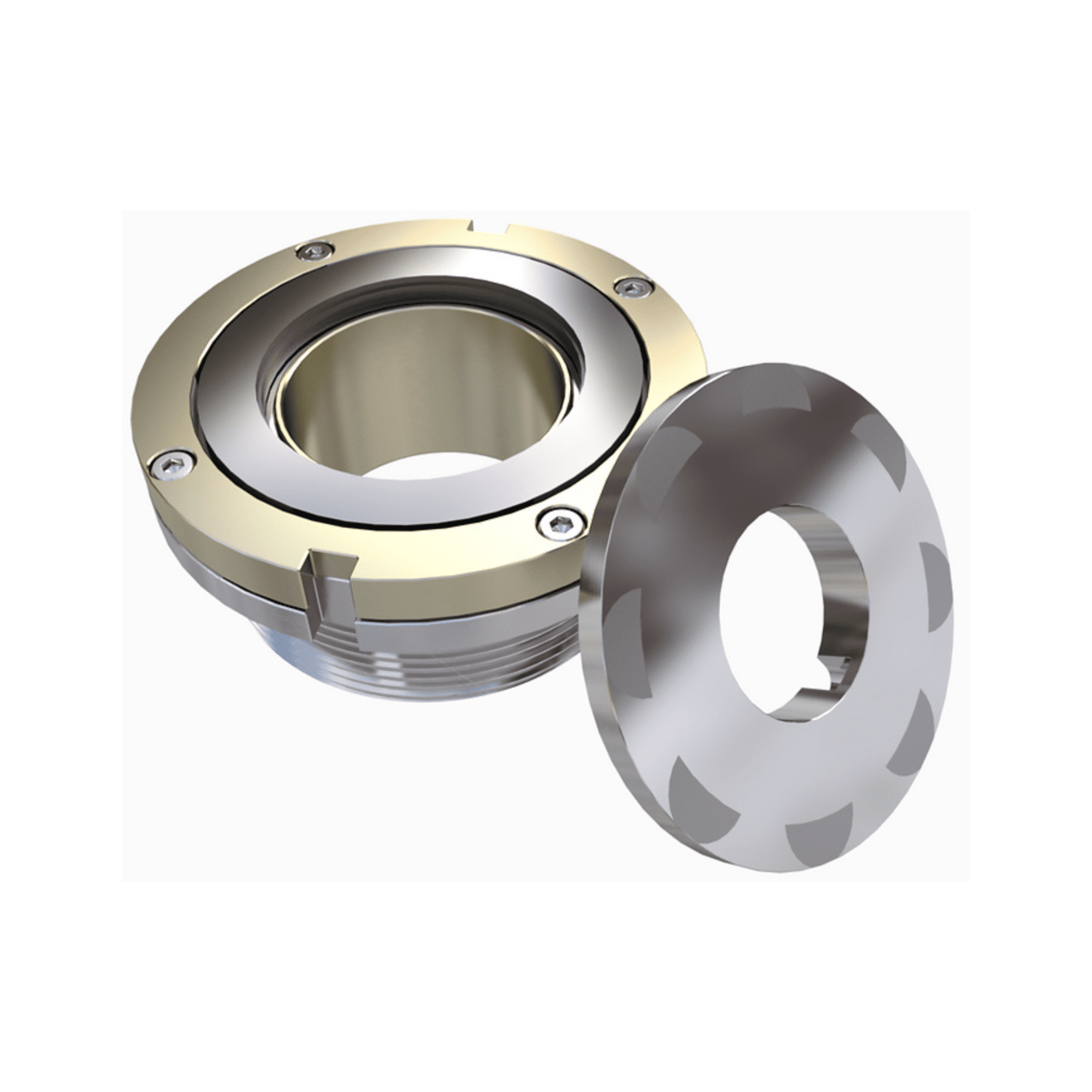

Seal Diagram:

| Part # | Components | Material |

|---|---|---|

| 101 | Mating Ring Rotor | NI |

| 102 | Seal Ring Stator | Hydrolon |

| 103 | Shims | Cu Alloy |

| 104 | O Ring for Seal Ring | 3145 |

| 105 | Nut Ring | SS-316 |

| 106 | Nut O Ring | 3145 |

| 107 | Anti Spark Sleeve | SS-316 |

| 108 | PTFE Packing Rings | PTFE |

Why Choose Orbit Fluid Solution LLP’s CR-DGS?

- Precision Engineering: Tailored solutions for cryogenic pumps.

- Advanced Materials: Ensures durability in extreme environments.

- Unmatched Expertise: Decades of experience in mechanical sealing solutions.

- Safety Compliance: Certified to meet industry and safety standards.