Description

Applications of Low Temperature Metal Bellow Seal ORM1

The ORM1 is engineered for use in a wide range of industrial applications:

- Chemical Industry: Ideal for handling chemical fluids with varying temperatures and aggressive compositions.

- Oil & Gas: Designed to seal high-temperature hydrocarbons in extraction, processing, and transport systems.

- Pulp & Paper: Provides reliable sealing for equipment exposed to heated liquids and process chemicals.

- Petrochemical Plants: Ensures seamless operation in extreme temperature conditions during chemical reactions and processing.

- Pharmaceutical Sector: Delivers precise sealing for contamination-sensitive processes in pharmaceutical production.

Key Operating Parameters

- Shaft Diameter: 18 to 150 mm

- Pressure Handling: Up to 10 Bars

- Temperature Range: -20°C to 180°C

- Rotational Speed: Up to 25 m/s

Material Specifications

The ORM1 seal is constructed using premium-grade materials to ensure exceptional performance, longevity, and resistance to harsh operating conditions:

- Seal Faces:

- Carbon

- Silicon Carbide (SiC)

- Tungsten Carbide (TC)

- Secondary Seals:

- FFKM (Perfluoroelastomer)

- FKM (Viton)

- PTFE

- Metal Components:

- Stainless Steel (SS-316)

- Hastelloy-C

- Inconel-718

- Bellows:

- Inconel-718

- Hastelloy-C

- AM-350

Unique Features of the ORM1 Metal Bellow Seal

- High Axial Flexibility: Compensates for shaft misalignment, thrust movement, or lack of concentricity, ensuring consistent sealing performance.

- Inherently Balanced Design: Reduces heat generation and friction, extending the seal’s operational life.

- Compact Construction: Requires minimal axial and radial space, making it ideal for compact systems.

- No Dynamic O-Rings: Eliminates shaft or sleeve damage caused by dynamic O-ring fretting, improving durability and reducing maintenance needs.

- Easy Installation: Simplified design ensures quick and hassle-free installation.

- Minimal Components: Reduces potential failure points, improving reliability and ease of maintenance.

Advantages of Choosing ORM1 Low Temperature Metal Bellow Seal

- Enhanced Durability: Resistant to extreme temperatures, pressure fluctuations, and aggressive fluids.

- Corrosion Resistance: Premium materials like Hastelloy-C and Inconel-718 offer excellent resistance to corrosion in harsh environments.

- Customizable Options: Torque transmission and seal configurations can be tailored to application-specific requirements.

- Energy Efficiency: Inherent balance minimizes energy losses, reducing operational costs.

- Longevity: Eliminates common failure points such as fretting, ensuring extended service life and fewer replacements.

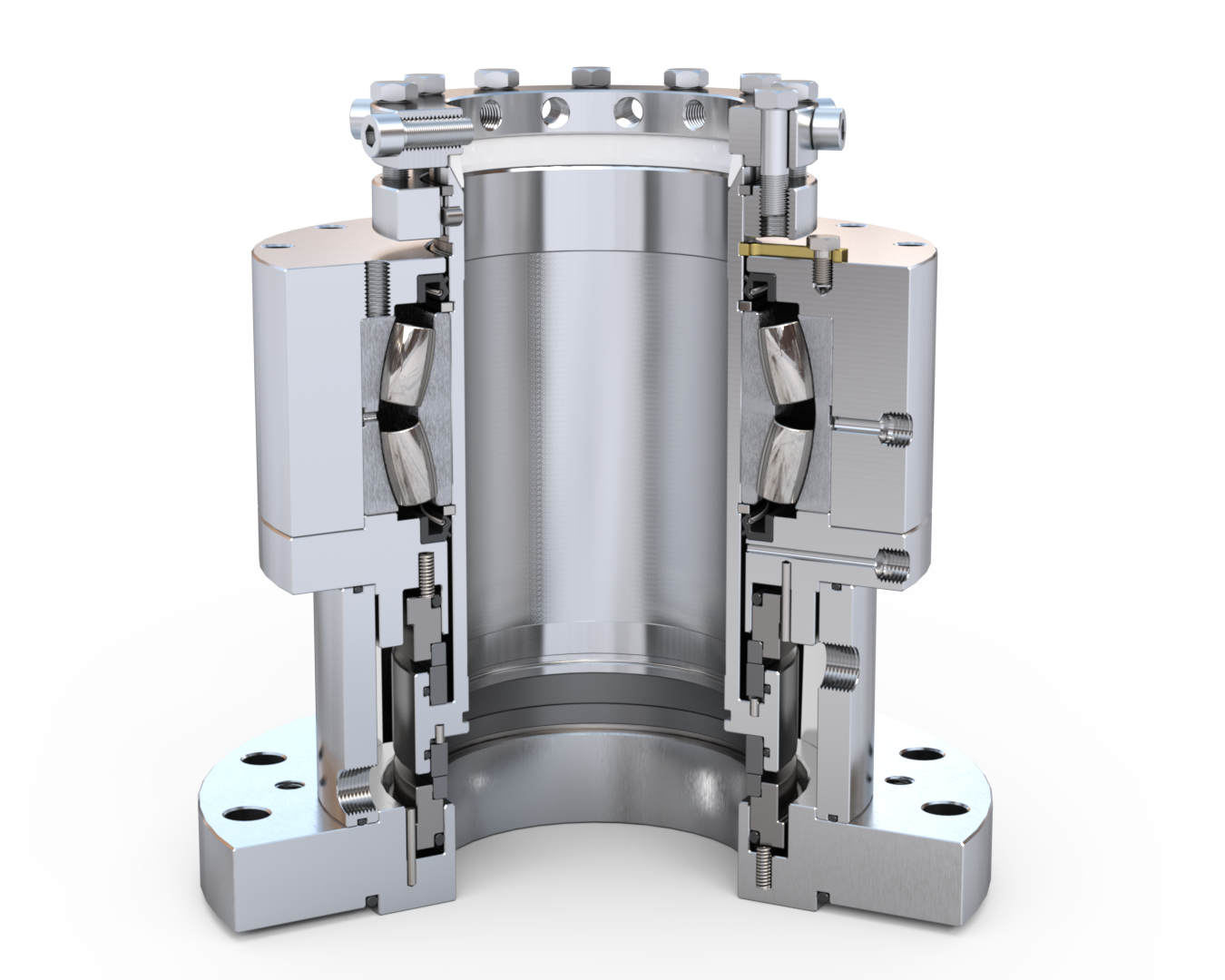

Seal Diagram

Dimensional Data

Dimensional Data Metrics| Seal Size/D1 mm | D2 | L1 |

|---|---|---|

| 18 | 32 | 27.5 |

| 20 | 33.3 | 27.5 |

| 22 | 36 | 27.5 |

| 24 | 38.1 | 30 |

| 25 | 39 | 30 |

| 28 | 42 | 32.5 |

| 30 | 44 | 32.5 |

| 32 | 46 | 32.5 |

| 33 | 47 | 32.5 |

| 35 | 49.2 | 32.5 |

| 38 | 52.4 | 34 |

| 40 | 55.6 | 34 |

| 43 | 58.7 | 34 |

| 45 | 58.7 | 34 |

| 48 | 61.9 | 34 |

| 50 | 65.1 | 34.5 |

| 53 | 68.3 | 34.5 |

| 55 | 71 | 34.5 |

| 60 | 74.6 | 39.5 |

| 65 | 84.1 | 39.5 |

| 70 | 87.3 | 45 |

| 75 | 95.3 | 45 |

| 80 | 98.4 | 44.5 |

| 85 | 104.8 | 44.5 |

| 90 | 108 | 49.5 |

| 95 | 114.3 | 49.5 |

| 100 | 120.7 | 49.5 |

| 105 | 131.7 | 48.3 |

| 110 | 138.1 | 48.3 |

| 115 | 144.5 | 48.3 |

| 120 | 144.5 | 48.3 |

| 125 | 150.8 | 48.3 |

| 130 | 157.8 | 48.3 |

| 140 | 170.5 | 48.3 |

| 150 | 176.9 | 48.3 |

Industries Benefiting from ORM1 Metal Bellow Seal

The ORM1 is trusted by leading industries worldwide for its unmatched performance and reliability:

- Chemical Processing: For high-temperature sealing of corrosive and reactive chemicals.

- Oil & Gas Exploration and Refining: Ensures leak-proof performance in crude oil and natural gas systems.

- Pulp & Paper Manufacturing: Handles challenging chemical and temperature conditions with ease.

- Petrochemical Industry: Delivers reliable sealing in processes involving hydrocarbons and other petrochemical substances.

- Pharmaceutical Production: Ensures precision sealing in sterile and contamination-sensitive environments.

Typical Use Cases

- Hydrocarbon Sealing: Reliable operation in oil refineries and petrochemical plants.

- High-Temperature Fluids: Effective in sealing hot oils, ensuring smooth and uninterrupted operations.

- Aggressive Chemical Fluids: Handles fluids with corrosive and abrasive properties without compromise.

- Dynamic Systems: Maintains performance even with axial movements or shaft misalignments.

Why Choose Orbit Fluid Solution LLP?

Orbit Fluid Solution LLP has established itself as a leader in mechanical sealing solutions since 1990. With a commitment to engineering excellence, innovative designs, and customer satisfaction, Orbit Fluid Solution LLP ensures each product meets the highest industry standards.

Key Differentiators:

- Over 30 years of expertise in sealing technology.

- Global reach and trusted by leading industries worldwide.

- Premium-grade materials for enhanced durability.

- Tailored solutions to meet specific industrial needs.

- Rigorous quality assurance and testing protocols.

Optimize your operations with the Low Temperature Metal Bellow Seal ORM1 from Orbit Fluid Solution LLP. Designed to deliver superior performance and reliability, this seal is your trusted solution for high-temperature applications.