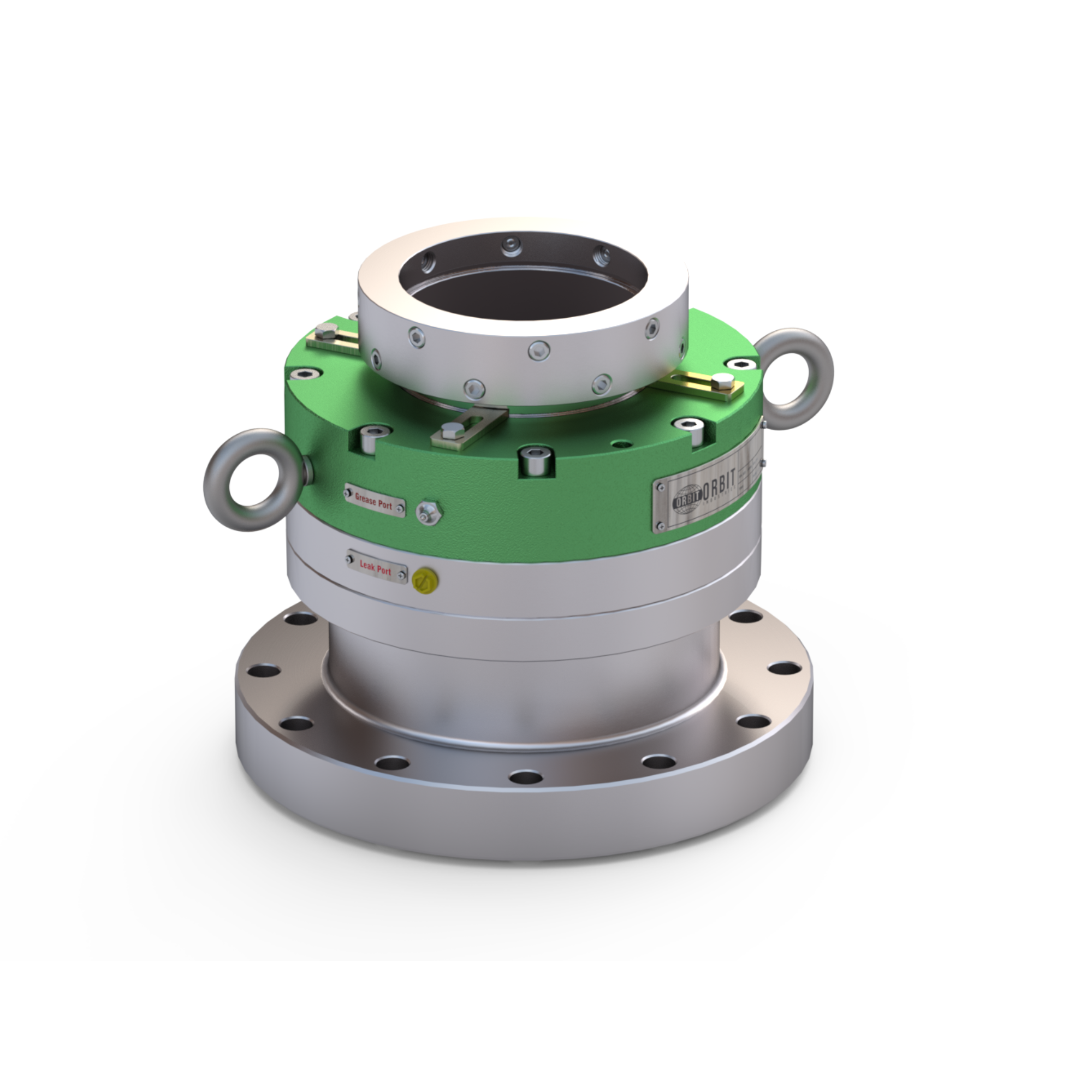

Description

Applications

The Glass Lined Reactor Seal – Type 806/805B-T is suitable for:

- Top-entry glass-lined and stainless-steel vessels

- Chemical reactors handling highly corrosive substances

- Sterile and biochemistry applications

Industries Served

This seal is ideal for operations in:

- Oil & Gas: Robust performance in handling high-pressure, corrosive media.

- Pharmaceutical: Meets stringent hygiene and sterility requirements.

- Chemical: Designed for highly reactive and aggressive chemical environments.

- Paper & Pulp: Reliable under harsh operational conditions.

- Food & Beverage: Safe and hygienic sealing solutions.

- Mining: Withstands abrasive conditions while ensuring durability.

- Petrochemicals: Exceptional sealing integrity in handling volatile compounds.

Operating Parameters

- Shaft Diameter: 40 to 125 mm

- Pressure Range: Vacuum to 45 bar

- Temperature Range: -80°C to +350°C

- Speed: Up to 500 RPM

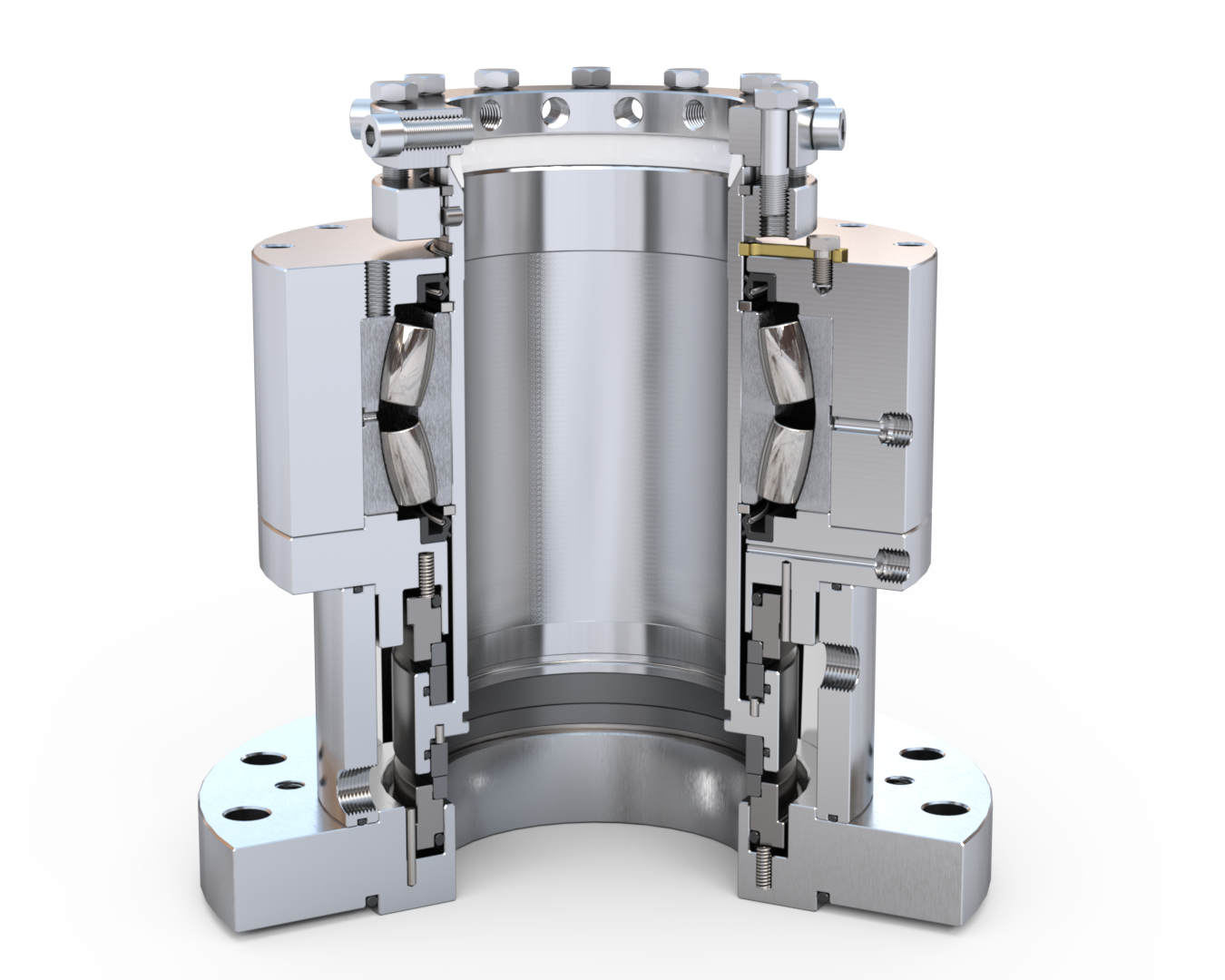

Seal Diagram

Dimensional Data

Dimensional Data Metrics| D1 | D2 | D6 | N x t | D4 | D3 | D5 | L1 | L2 |

|---|---|---|---|---|---|---|---|---|

| 40 | 38 | 175 | 4x18 | 110 | 102 | 145 | 181 | 28 |

| 50 | 48 | 240 | 8x18 | 176 | 138 | 210 | 192 | 28 |

| 60 | 58 | 275 | 8x22 | 204 | 188 | 240 | 200 | 28 |

| 80 | 78 | 305 | 8x22 | 234 | 212 | 270 | 236 | 34 |

| 100 | 98 | 395 | 12x22 | 313 | 268 | 350 | 236 | 34 |

| 100 | 98 | 395 | 12x22 | 313 | 268 | 350 | 236 | 34 |

| 125 | 120 | 505 | 4x22 | 422 | 306 | 460 | 256 | 40 |

| 140 | 135 | 505 | 4x22 | 422 | 306 | 460 | 272 | 40 |

| 160 | 150 | 505 | 4x22 | 422 | 306 | 460 | 272 | 40 |

| 160 | 150 | 505 | 4x22 | 422 | 306 | 460 | 272 | 40 |

| 160 | 150 | 565 | 4x26 | 474 | 356 | 515 | 272 | 40 |

Seal Features

- Balanced Design: Optimized for consistent performance under varying pressures.

- Dry Running Capability: Special-grade seal face materials enable reliable dry operation.

- Vacuum Adaptability: Reverse balance seal ring enhances vacuum sealing capabilities.

- Chemical Compatibility: Virgin PTFE-wrapped O-Rings ensure durability with a wide range of chemicals.

- PTFE Protection: Clamping arrangement prevents damage to glass-lined shafts.

- Factory-Assembled Cartridge Unit: Ready to install and rigorously quality-tested.

Materials of Construction

- Seal Faces: Carbon, Silicon Carbide (SiC), Tungsten Carbide (TC)

- Secondary Seals: Virgin PTFE O-Rings (Double & Single Wrapped)

- Metal Components: SS-316, Hastelloy-C

Why Choose Orbit Fluid Solution LLP?

- Corrosion Resistance: Engineered for the toughest chemical environments.

- Global Standards Compliance: Designed to meet DIN 28138 and DIN 27136 standards.

- Dimensional Precision: Detailed data ensures compatibility with your equipment.

- Custom Solutions: Tailored options available for unique industrial needs.

- Trusted Expertise: Decades of leadership in mechanical sealing solutions.