Description

Applications

The HR20-C Dry Running Single Seal is designed for:

- Top-entry steel and stainless-steel vessels

- Glass-lined vessels for sterile and sensitive applications

- Mixers in food, pharmaceutical, and biochemistry processes

Industries Served

This seal is highly suitable for:

- Biofuels: Ensures reliable sealing for renewable energy processes.

- Chemical: Withstands aggressive and reactive chemical environments.

- Food & Beverage: Provides contamination-free sealing for hygienic operations.

- Marine: Handles the unique demands of maritime mixing systems.

- Oil & Gas: Performs effectively under high-pressure and high-temperature conditions.

- Pulp & Paper: Offers robust sealing for abrasive materials and high-speed mixing.

- Sugar Industries: Maintains efficiency in demanding sugar processing environments.

- Cement Plants: Reliable for sealing mixers in tough industrial conditions.

- Petrochemicals: Exceptional performance for handling volatile substances.

- Pharmaceutical: Meets the stringent standards for clean and sterile sealing solutions.

Operating Parameters

- Shaft Diameter: 40 to 125 mm

- Pressure Range: Vacuum to 5 bar

- Temperature Range: -80°C to +350°C

- Speed: Up to 500 RPM

Seal Features

- Balanced Design: Optimized for consistent performance under varying pressures.

- Dry Running Seal Face: Specially crafted to excel in non-lubricated environments.

- Vacuum Adaptability: Reverse balance seal ring ensures superior vacuum sealing.

- Chemical Compatibility: Virgin PTFE-wrapped O-rings offer durability with a wide range of chemicals.

- PTFE Protection: Prevents damage to glass-lined shafts during operation.

- Factory-Assembled Cartridge Unit: Pre-tested and ready for easy installation.

Materials of Construction

- Seal Faces: Carbon, Silicon Carbide (SiC), Tungsten Carbide (TC)

- Secondary Seals: Virgin PTFE O-rings (Double & Single Wrapped)

- Metal Components: SS-316, Hastelloy-C

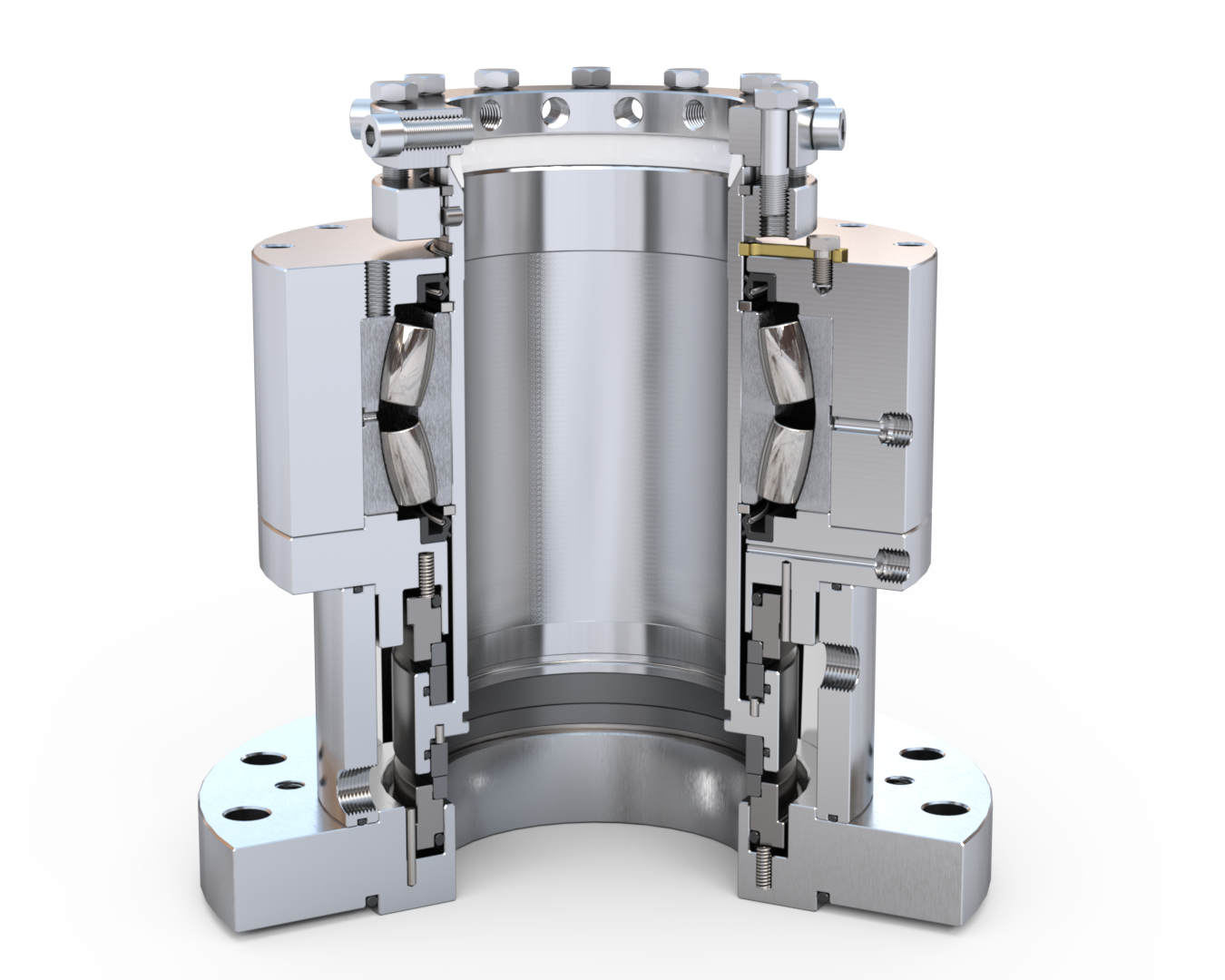

Seal Diagram

Dimensional Data

Dimensional Data Metrics| D1 | D2 | D3 | D4 | S | ∅N x t |

|---|---|---|---|---|---|

| 25 | – | 63.5 | 148 | 100 | 11x 4 |

| 28 | 55 | 66.6 | 148 | 100 | 11x 4 |

| 30 | 55 | 69.8 | 148 | 100 | 11x 4 |

| 32 | 60 | 69.8 | 153 | 105 | 11x 4 |

| 35 | 60 | 73 | 153 | 105 | 11x 4 |

| 38 | 65 | 76.2 | 158 | 110 | 11x 4 |

| 40 | 65 | 79.3 | 158 | 110 | 11x 4 |

| 45 | 68 | 85.7 | 163 | 120 | 11x 4 |

| 50 | 73 | 88.9 | 178 | 125 | 14x 4 |

| 55 | 78 | 95.2 | 183 | 130 | 14x 4 |

| 60 | 85 | 98.4 | 188 | 135 | 14x 6 |

| 65 | 90 | 104.7 | 193 | 140 | 14x 6 |

| 70 | 95 | 107.9 | 198 | 145 | 14x 6 |

| 75 | 100 | 114.3 | 203 | 150 | 14x 6 |

| 80 | 105 | 120.6 | 208 | 155 | 14x 6 |

| 85 | 110 | 123.8 | 213 | 160 | 14x 6 |

| 90 | 115 | 130.2 | 218 | 165 | 14x 6 |

| 95 | 120 | 133.3 | 223 | 170 | 14x 6 |

| 100 | 125 | 139.7 | 228 | 175 | 14x 8 |

| 105 | 130 | 142.9 | 233 | 180 | 14x 8 |

| 110 | 135 | 149.2 | 238 | 185 | 14x 8 |

| 115 | 140 | 155.5 | 267 | 196 | 18x 8 |

| 120 | 140 | 158.7 | 270 | 200 | 18x 8 |

| 125 | 140 | 165.1 | 277 | 206 | 18x 8 |

| 130 | 150 | 168.2 | 285 | 210 | 18x 8 |

| 135 | 150 | 174.6 | 290 | 215 | 18x 8 |

| 140 | 160 | 180.9 | 297 | 221 | 18x 8 |

| 145 | 160 | 184.1 | 300 | 226 | 18x 8 |

| 150 | 160 | 190.5 | 305 | 230 | 18x 8 |

Why Choose Orbit Fluid Solution LLP?

- Efficiency & Reliability: Designed to meet the demands of modern mixers.

- Standards Compliance: Built in accordance with DIN 28138 and DIN 27136.

- Custom Solutions: Specially engineered options available for unique needs.

- Global Expertise: Trusted by industries worldwide for superior sealing solutions.