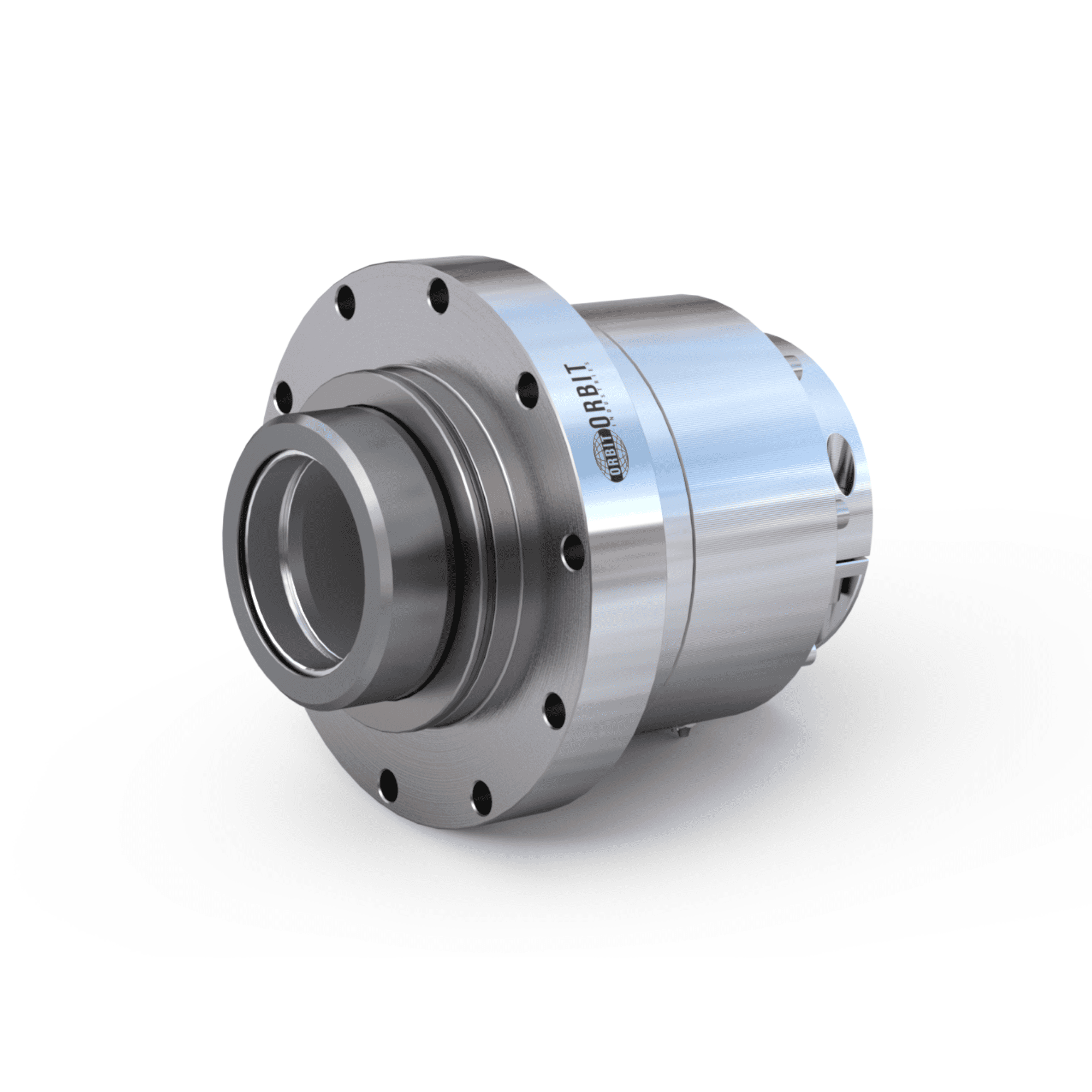

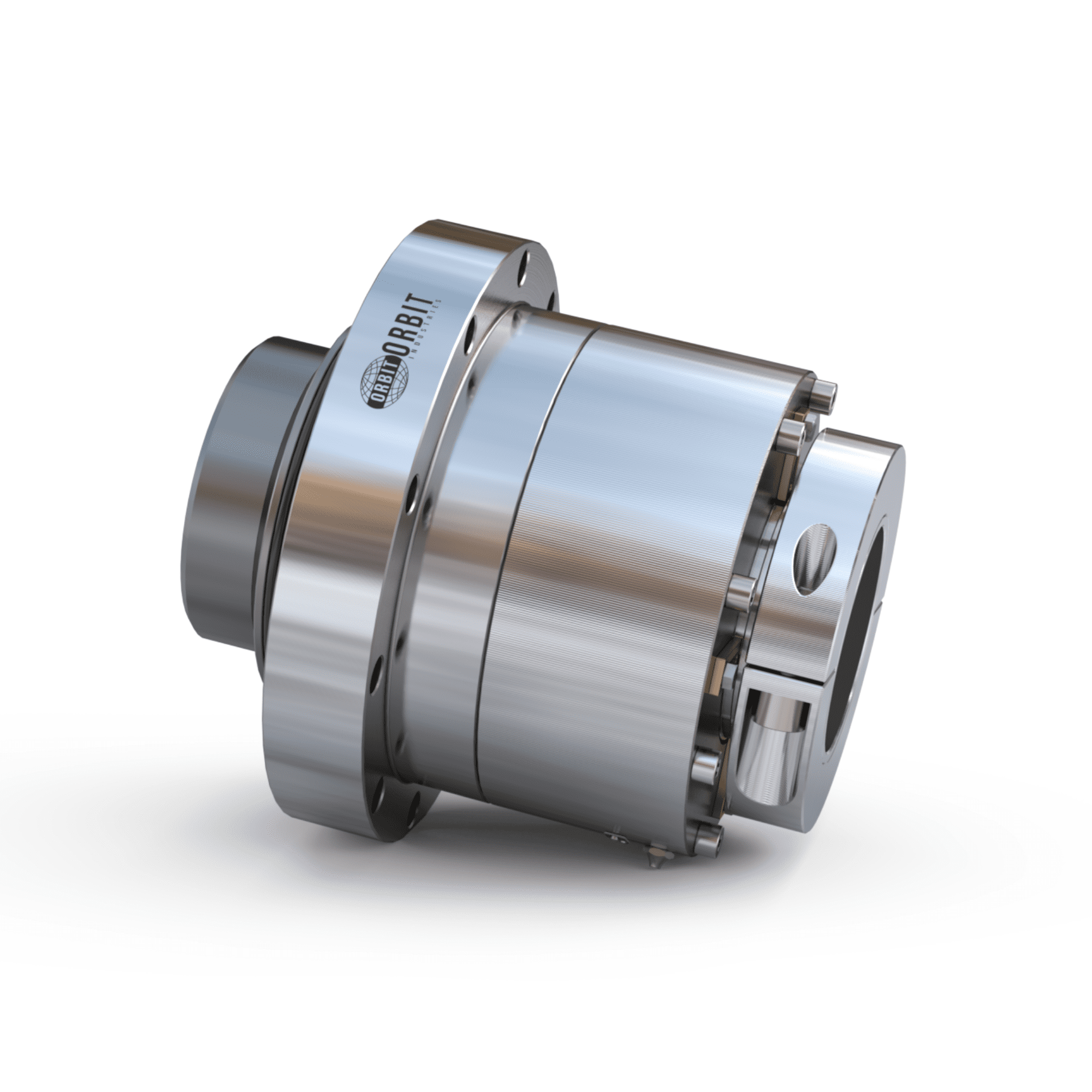

Description

Applications:

The Side Entry Agitator Seal is ideal for:

- Side entry mixers

- Agitated vessels

- Mixers

- Reactors

Industries Served:

Our Side Entry Agitator Seal serves various industries, including:

- Oil & Gas: Providing reliable sealing solutions for critical processes in oil and gas applications.

- Pharmaceutical: Offering sanitary and reliable sealing solutions for pharmaceutical processing equipment.

- Chemical: Ensuring durable and efficient sealing solutions for chemical processing equipment.

- Paper & Pulp: Providing reliable sealing solutions for pulp and paper processing equipment.

- Food & Beverage: Ensuring sanitary and reliable sealing solutions for food and beverage processing equipment.

- Mining: Offering durable and efficient sealing solutions for mining processing equipment.

- Biofuels: Providing sealing solutions for biofuel processing equipment.

- Marine: Ensuring reliable sealing solutions for marine applications.

- Sugar Industries: Ensuring sanitary and reliable sealing solutions for sugar processing equipment.

- Cement Plants: Offering durable and efficient sealing solutions for cement processing equipment.

- Petrochemicals: Providing high-performance sealing solutions for petrochemical processing equipment.

Operating Parameters:

- Shaft Diameter: 40 to 150 mm

- Vessel Pressure: Vacuum to 15 bar

- Temperature: -80°C to +350°C

- Speed: Up to 500 min-1

Seal Diagram:

Dimensional Data:

Dimensional Data Metrics | D1 | D2 | D3 | D4 | D5 | L1 | L2 | L3 | L4 |

| 20 | 52 | 117 | 140 | 118 | 22 | 30.5 | 157.5 | 196.5 |

| 25 | 58 | 124 | 150 | 128 | 22 | 30.5 | 167 | 210 |

| 30 | 62 | 134 | 165 | 138 | 26 | 30.5 | 174 | 215 |

| 35 | 68 | 140 | 175 | 148 | 26 | 30.5 | 174 | 215 |

| 40 | 75 | 146 | 175 | 148 | 28 | 34.5 | 180 | 225 |

| 45 | 83 | 150 | 175 | 148 | 28 | 34.5 | 180 | 226 |

| 50 | 90 | 170 | 195 | 168 | 30 | 34.5 | 190 | 250 |

| 55 | 95 | 175 | 205 | 178 | 30 | 34.5 | 200 | 258 |

| 60 | 100 | 180 | 205 | 178 | 30 | 34.5 | 200 | 258 |

| 65 | 110 | 190 | 220 | 188 | 30 | 40.5 | 210 | 268 |

| 70 | 115 | 195 | 230 | 198 | 30 | 40.5 | 210 | 268 |

| 75 | 120 | 200 | 230 | 198 | 30 | 40.5 | 216 | 272 |

| 80 | 130 | 210 | 240 | 208 | 32 | 45 | 225 | 285 |

| 85 | 135 | 215 | 250 | 218 | 32 | 45 | 230 | 308 |

| 90 | 140 | 230 | 260 | 228 | 35 | 45 | 245 | 315 |

| 95 | 145 | 235 | 270 | 238 | 35 | 45 | 245 | 325 |

| 100 | 150 | 240 | 270 | 238 | 40 | 45 | 260 | 325 |

| 110 | 160 | 255 | 290 | 258 | 40 | 50 | 266 | 340 |

| 120 | 172 | 265 | 305 | 268 | 40 | 52.5 | 270 | 350 |

| 130 | 185 | 275 | 315 | 278 | 40 | 52.5 | 270 | 358 |

| 140 | 195 | 290 | 335 | 298 | 41 | 52.5 | 285 | 365 |

| 150 | 205 | 300 | 335 | 298 | 45 | 52.5 | 290 | 380 |

| 160 | 220 | 330 | 355 | 325 | 45 | 52.5 | 290 | 390 |

| 170 | 230 | 345 | 375 | 358 | 45 | 52.5 | 290 | 405 |

| 180 | 240 | 365 | 395 | 358 | 45 | 55.5 | 300 | 418 |

| 190 | 270 | 395 | 425 | 388 | 60 | 57.5 | 335 | 465 |

| 200 | 280 | 395 | 425 | 388 | 60 | 57.5 | 335 | 465 |

Materials of Construction:

- Seal Face: Silicon Carbide (SiC)

- O-Ring: Virgin PTFE

- Seal Housing: Stainless Steel (SS316)

- Shaft Sleeve: Carbon Steel (CS) or Stainless Steel (SS316)

- Other Components: High-quality materials, including stainless steel, carbon steel, and engineered plastics.

Key Features:

- Unique Seal Design: Engineered to provide superior sealing integrity in side entry mixer applications.

- Hydraulically Balanced Inboard Seal Ring: Ensures optimal performance in demanding conditions.

- Vergin PTFE Wrapped O-Rings: Compatible with a wide range of chemicals.

- PTFE Protected V Packing Design: Ensures reliable sealing in slurry applications.

- Complete Cartridge Unit: Factory-assembled and tested for easy installation and maintenance.

Why Choose Orbit Fluid Solution LLP?

At Orbit Fluid Solution LLP, we pride ourselves on providing high-quality mechanical seals that meet the demanding needs of various industries. Our Side Entry Agitator Seal is designed to provide superior sealing integrity, reliability, and efficiency. By choosing Orbit, you can expect:

- Expert Technical Support: Our team of experts is available to provide technical support and guidance.

- Customized Solutions: We offer customized seal solutions to meet specific application requirements.

- High-Quality Materials: We use only the highest-quality materials.

Maximize efficiency in your side entry agitator operations. Get in touch today to discover the ideal seal solution!