Description

Applications

The Type 80B3S Slurry Cartridge Seal delivers high performance in various operational scenarios:

- Slurry and Abrasive Media: Engineered to handle challenging applications where solids are present.

- Pumps and Reactors: Ideal for single and dual seal configurations in ANSI and DIN standard pumps.

- Solid Particle Media: Features isolated springs that prevent choking and ensure reliable sealing even in harsh environments.

Industries Served

The Type 80B3S Slurry Cartridge Seal is perfectly suited for the following industries:

- Chemical Processing: Effectively manages corrosive and abrasive chemical slurries.

- Food & Beverage: Ensures hygienic sealing for processes involving thick syrups and slurries.

- Mining & Minerals: Provides superior sealing in abrasive mining slurries.

- Oil & Gas: Handles challenging upstream and downstream processes with solid-laden media.

- Pulp & Paper: Offers reliable performance in thick pulp and slurry applications.

- Water & Wastewater: Ensures efficient handling of sludges and abrasive particulates.

- Sugar Industries: Designed for high-performance sealing in sugar slurry applications.

- Cement Plants: Resists wear and ensures operational continuity in cement slurries.

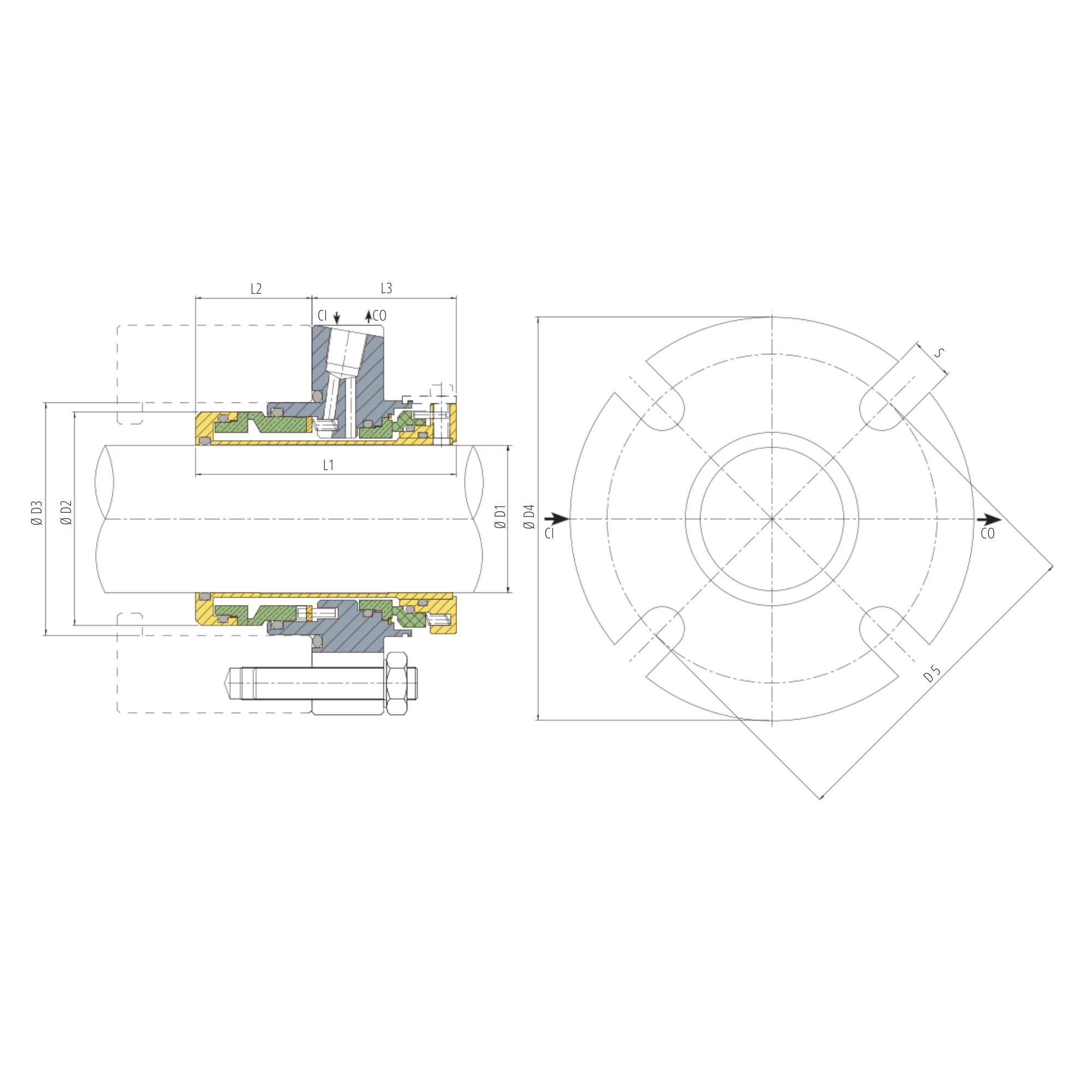

Seal Diagram

Dimensional Data

Dimensional Data Metrics| D1 | D2 | D3 | D4 | D5 | L1 | L2 | L3 | S |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.57 | 1.63 | 4.1 | - | 3.2 | 1.88 | 2.05 | 0.44 |

| 1.125 | 1.69 | 1.75 | 4.1 | - | 3.2 | 1.88 | 2.05 | 0.44 |

| 1.25 | 1.83 | 1.88 | 4.1 | - | 3.2 | 1.88 | 2.05 | 0.44 |

| 1.375 | 1.94 | 2 | 4.4 | 3.33 | 3.2 | 1.88 | 2.05 | 0.57 |

| 1.5 | 2.19 | 2.25 | 4.5 | 3.55 | 3.2 | 1.97 | 2.11 | 0.57 |

| 1.625 | 2.31 | 2.38 | 5 | 3.68 | 3.2 | 1.97 | 2.11 | 0.57 |

| 1.75 | 2.44 | 2.5 | 5.5 | 3.8 | 3.2 | 1.97 | 2.11 | 0.57 |

| 1.875 | 2.56 | 2.63 | 5.5 | 3.93 | 3.2 | 1.97 | 2.11 | 0.57 |

| 2 | 2.69 | 2.75 | 5.5 | 4.12 | 3.2 | 1.97 | 2.11 | 0.57 |

| 2.125 | 2.81 | 2.88 | 6 | 4.37 | 3.2 | 1.97 | 2.11 | 0.69 |

| 2.25 | 2.94 | 3 | 6 | 4.49 | 3.2 | 1.97 | 2.11 | 0.69 |

| 2.375 | 3.06 | 3.13 | 6 | 4.55 | 3.2 | 1.97 | 2.11 | 0.69 |

| 2.5 | 3.19 | 3.25 | 6.5 | 4.74 | 3.2 | 1.97 | 2.11 | 0.69 |

| 2.625 | 3.31 | 3.38 | 6.5 | 4.99 | 3.2 | 1.97 | 2.11 | 0.69 |

| 2.75 | 3.67 | 3.75 | 7.75 | 5.4 | 4.25 | 2.5 | 2.5 | 0.69 |

| 2.875 | 3.79 | 3.88 | 7.8 | 5.48 | 4.25 | 2.5 | 2.5 | 0.69 |

| 3 | 3.91 | 4 | 7.95 | 5.63 | 4.25 | 2.5 | 2.5 | 0.69 |

| 3.125 | 4.04 | 4.13 | 7.95 | 5.78 | 4.25 | 2.5 | 2.5 | 0.69 |

| 3.25 | 4.16 | 4.25 | 8.2 | 5.91 | 4.25 | 2.5 | 2.5 | 0.69 |

| 3.375 | 4.29 | 4.38 | 8.3 | 5.98 | 4.25 | 2.5 | 2.5 | 0.81 |

| 3.5 | 4.41 | 4.5 | 8.44 | 6.15 | 4.25 | 2.5 | 2.5 | 0.81 |

| 3.625 | 4.54 | 4.63 | 8.5 | 6.28 | 4.25 | 2.5 | 2.5 | 0.81 |

| 3.75 | 4.66 | 4.75 | 8.7 | 6.35 | 4.25 | 2.5 | 2.5 | 0.81 |

| 3.875 | 4.79 | 4.88 | 8.84 | 6.48 | 4.25 | 2.5 | 2.5 | 0.81 |

| 4 | 4.91 | 5 | 8.96 | 6.62 | 4.25 | 2.5 | 2.5 | 0.81 |

Materials of Construction

The Type 80B3S is built to last using high-quality materials:

- Seal Faces: Carbon, Silicon Carbide (SSiC), Tungsten Carbide (TC)

- Secondary Seals: FKM, FFKM, NBR

- Metal Components: SS-316, Hastelloy-C, Inconel-718

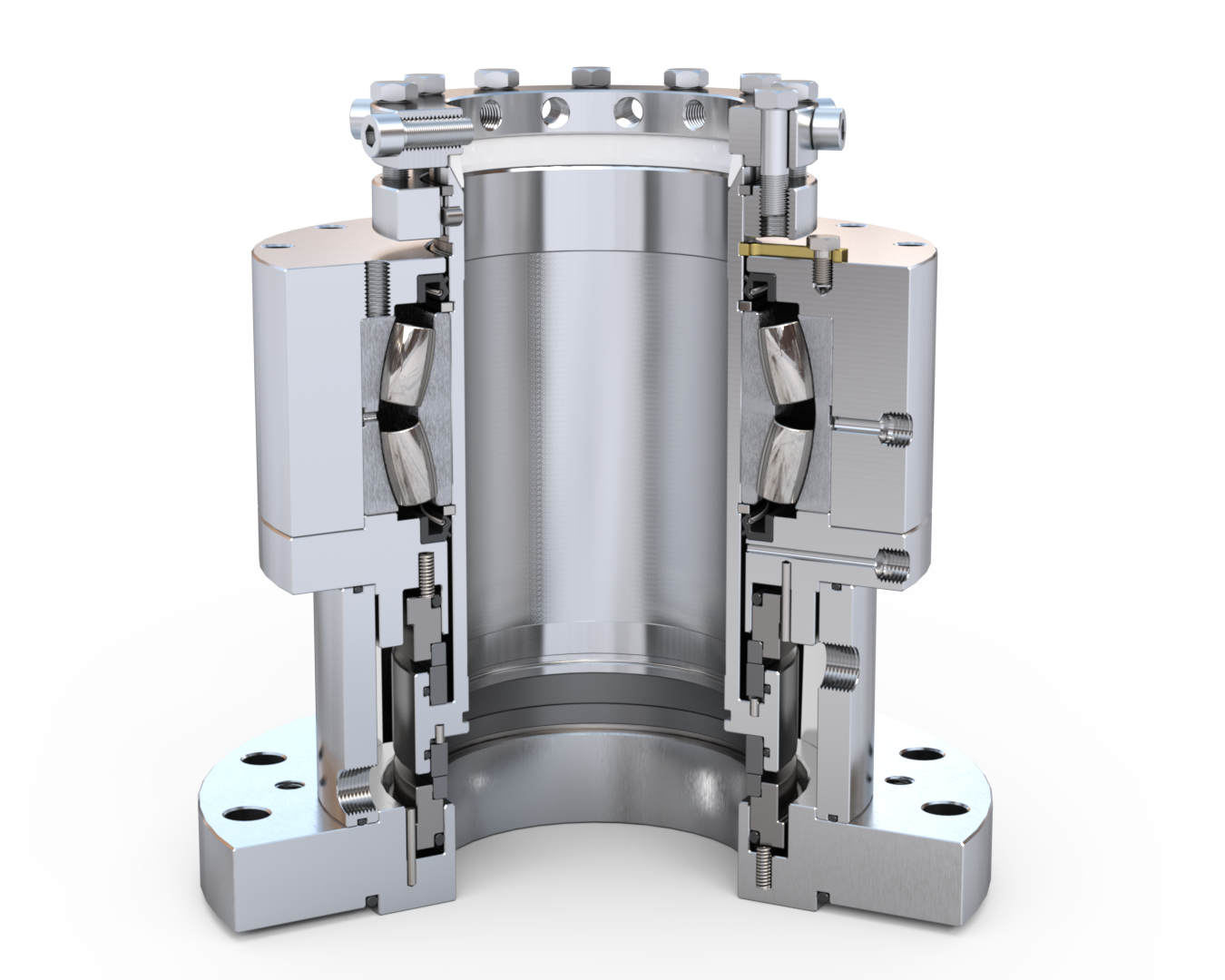

Key Features

- Designed for Solid-Laden Media: Handles abrasive and slurry applications effortlessly.

- Spring Isolation: Prevents clogging and ensures consistent performance.

- Minimal Axial and Radial Space: Compact design allows for easy installation.

- Robust Seal Faces: Provide excellent resistance to wear, abrasion, and corrosion.

- High-Quality Materials: Ensures durability in the most demanding conditions.

- Customizable Configurations: Suits various operational requirements.

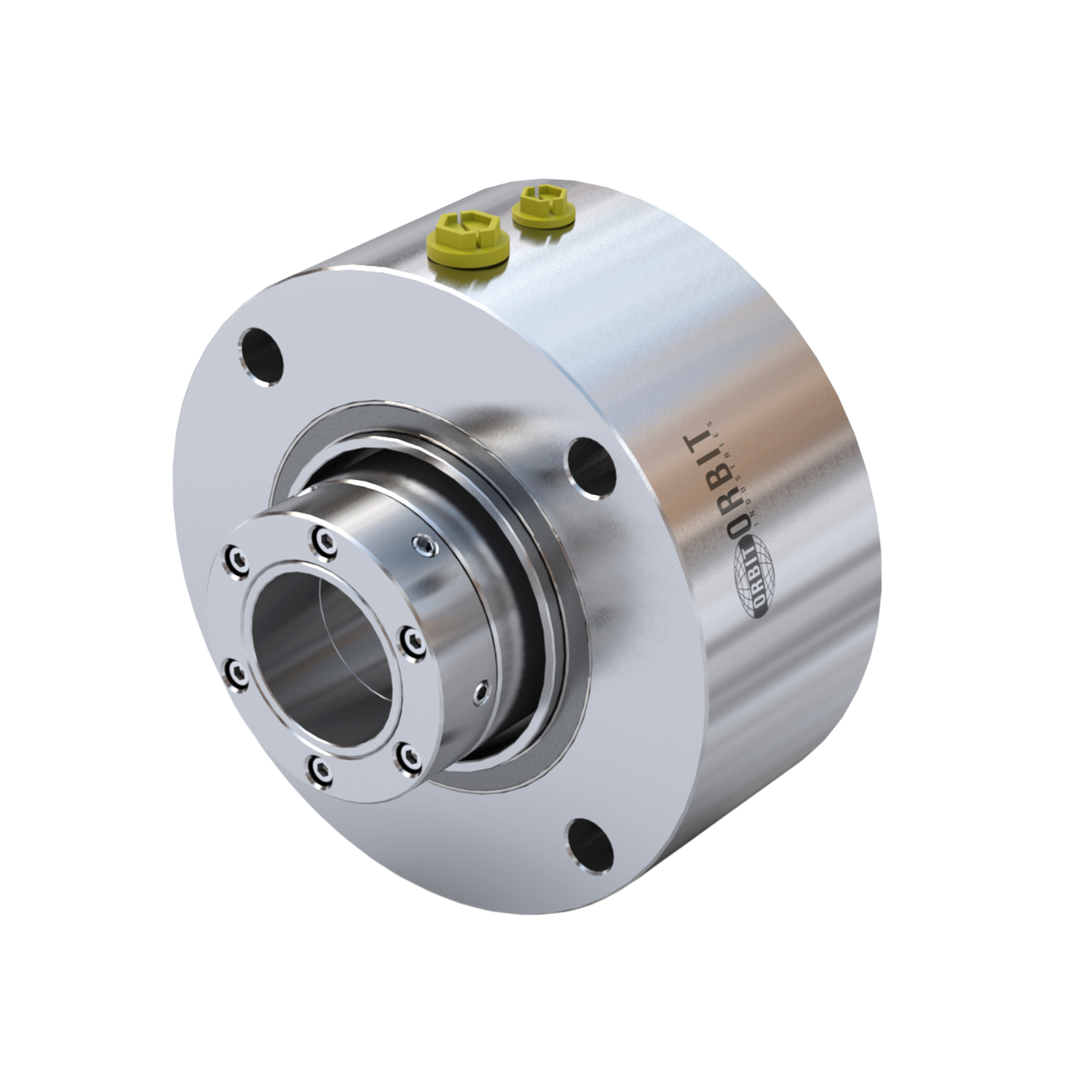

Why Choose Orbit Fluid Solution LLP?

With over three decades of excellence in mechanical sealing solutions, Orbit Fluid Solution LLP is dedicated to providing innovative and reliable products. The Slurry Cartridge Seal Type 80B3S reflects our commitment to quality and precision, ensuring maximum operational efficiency and minimal downtime for your industrial applications.