Description

Applications

The OR25 Rubber Bellow Seal is ideal for centrifugal pumps and rotating equipment handling dirty water and viscous fluids. Its robust design ensures superior performance in:

- Automotive: Enhances coolant system reliability in harsh conditions.

- Biofuels: Protects pumps handling biodiesel blends mixed with impurities.

- Food & Beverage: Offers hygienic and effective sealing for water with sediment.

- Marine: Withstands saltwater and debris in shipboard pumps.

- Metal & Glass-Working: Excels in cooling water systems for machining processes.

- Mining & Minerals: Handles abrasive slurry and sediment-laden water in mining applications.

- Power Generation: Seals pumps in cooling towers and condensers with dirty water.

- Pulp & Paper: Ensures smooth water flow in paper processing with contaminants.

- Water & Waste Water: Seals pumps in filtration systems for wastewater treatment.

- Petrochemicals: Reliable for auxiliary systems exposed to contaminated water.

- Pharmaceutical: Maintains hygiene while handling water with suspended solids.

Operating Parameters

- Shaft Diameter: 15 to 110 mm

- Pressure: Vacuum to 15 Bar

- Temperature: -20 to 140°C

- Speed: Up to 10 m/s

Materials

- Seal Faces: Carbon/Silicon Carbide/Tungsten Carbide/Aluminum Oxide

- Secondary Seals: NBR/FKM/FFKM/EPDM

- Metal Components: SS-316/SS-304

Features

- Easy Installation: Simplifies assembly, reducing downtime.

- Compact Design: Requires minimal axial and radial space for installation.

- Handles Highly Viscous Fluids: Excels in demanding fluid conditions.

- Rugged & Reliable: Built for durability and consistent performance.

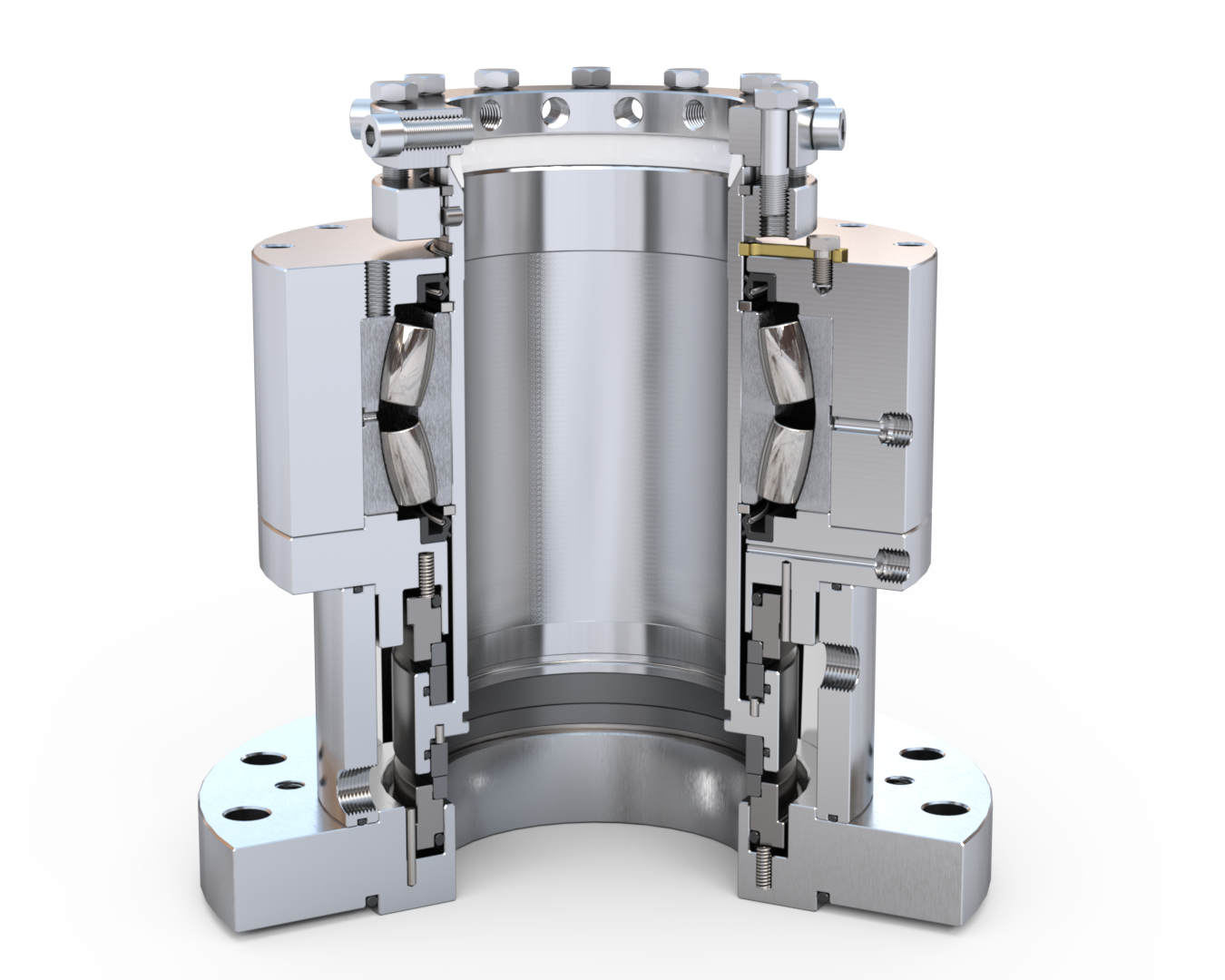

Seal Diagram

Dimensional Data

Dimensional Data Metrics| D1 | D2 | D3 | D4 | L | L1 | L2 | L3 |

|---|---|---|---|---|---|---|---|

| 14 | 28.5 | 30 | 27 | 17 | – | – | 6.6 |

| 16 | 28.5 | 30 | 27 | 17 | 28.4 | 33.4 | 6.6 |

| 18 | 32 | 33 | 33 | 19.5 | 30 | – | 7.5 |

| 20 | 37 | 38 | 35 | 21.5 | 30 | – | 7.5 |

| 22 | 37 | 38 | 37 | 21.5 | 30 | – | 7.5 |

| 24 | 42.5 | 44 | 39 | 22.5 | 32.5 | – | 7.5 |

| 25 | 42.5 | 44 | 40 | 23 | 32.5 | – | 7.5 |

| 28 | 49 | 50 | 43 | 26.5 | 35 | 42.5 | 7.5 |

| 30 | 49 | 50 | 45 | 26.5 | 35 | – | 7.5 |

| 32 | 53.5 | 55 | 48 | 27.5 | 35 | – | 7.5 |

| 33 | 53.5 | 55 | 48 | 27.5 | 35 | – | 7.5 |

| 35 | 57 | 59 | 50 | 28.5 | – | – | 7.5 |

| 38 | 59 | 61 | 56 | 30 | 36 | 46 | 9 |

| 40 | 62 | 64 | 58 | 30 | 36 | – | 9 |

| 43 | 65.5 | 67 | 61 | 30 | 36 | – | 9 |

| 45 | 68 | 70 | 63 | 30 | 36 | – | 9 |

| 48 | 70.5 | 74 | 66 | 30.5 | 36 | 51 | 9 |

| 50 | 74 | 77 | 70 | 30.5 | – | – | 9.5 |

| 55 | 81 | 83 | 75 | 35 | 36.5 | 59 | 11 |

| 60 | 88.5 | 91 | 80 | 38 | 41.5 | 54.5 | 11 |

| 65 | 93.5 | 96 | 85 | 40 | 41.5 | – | 11 |

| 70 | 99.5 | 103 | 92 | 40 | – | – | 11.3 |

| 75 | 107 | 110 | 97 | 40 | – | – | 11.3 |

| 80 | 112 | 116 | 105 | 40 | – | – | 12 |

| 85 | 120 | 124 | 110 | 41 | – | – | 14 |

| 90 | 127 | 131 | 115 | 45 | – | – | 14 |

| 95 | 132 | 136 | 120 | 46 | – | – | 14 |

| 100 | 137 | 140 | 125 | 47 | – | – | 14 |

Why Choose Us?

- Engineering Excellence: Decades of expertise in designing cutting-edge sealing solutions.

- Precision Craftsmanship: High-grade materials ensure unmatched durability and reliability.

- Tailored Solutions: Customization options available to meet unique industrial needs.

- Global Trust: Serving industries worldwide with proven performance and innovation.

- Sustainability: Commitment to eco-friendly practices and long-lasting solutions.