Description

Applications

The Type 805 excels in providing reliable sealing in:

- Pumps: Effective fluid management at low pressures.

- Mixers & Rotating Equipment: Enhances operational efficiency in low-pressure scenarios.

- Single, Back-to-Back, Face-to-Face, or Tandem Configurations: Adaptable to diverse sealing requirements.

Industries Served

This versatile seal is suitable for a wide range of industries, including:

- Automotive: Ensures reliable performance in fluid systems.

- Biofuels: Facilitates efficient sealing in biofuel production systems.

- Food & Beverage: Compliant with stringent hygiene and safety standards.

- Mining & Minerals: Designed to withstand abrasive and slurry conditions.

- Oil & Gas: Offers effective sealing in high-pressure and corrosive environments.

- Power Generation: Guarantees operational reliability in power plants.

- Pulp & Paper: Excels in handling high-viscosity and slurry applications.

- Sugar Industries: Ensures smooth operations in sugar processing.

- Cement Plants: Durable performance in cement and material handling systems.

- Petrochemicals: Built to endure harsh chemical environments.

- Pharmaceutical: Provides high-precision sealing for contamination-sensitive processes.

Operating Parameters

The Type 805 delivers exceptional performance under these conditions:

- Shaft Diameter: 10 to 150 mm

- Pressure: Up to 10 Bars

- Temperature: -25°C to 220°C

- Speed: Up to 25 m/s

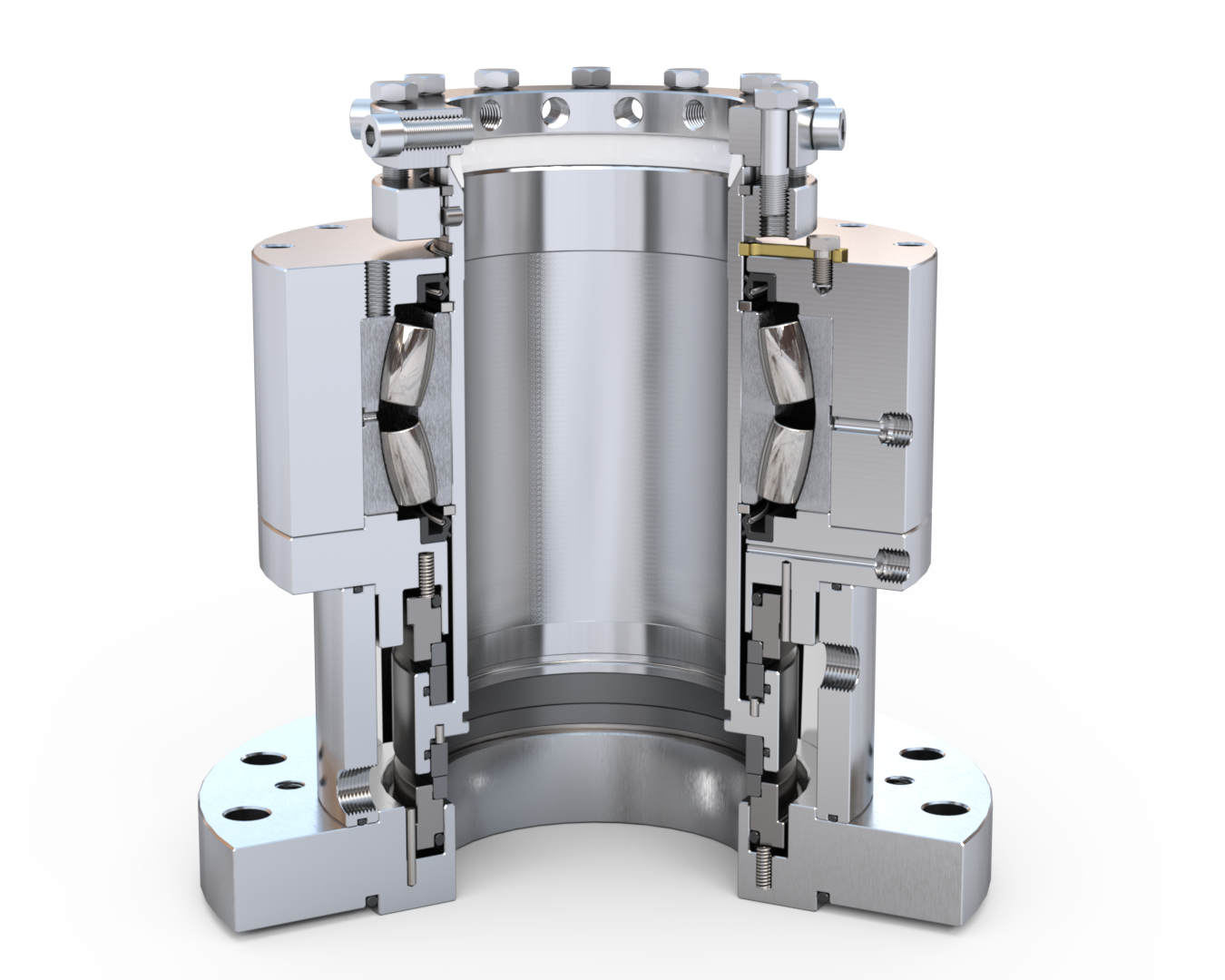

Seal Diagram

Dimensional Data

Dimensional Data Metrics| D1 | D2 | D3 | D4 | D5 | d1 | d2 | a | L1 | L2 | L3 |

|---|---|---|---|---|---|---|---|---|---|---|

| 14 | 24 | 26 | 24.6 | 18.4 | 3 | 2.5 | 1.5 | 23 | 11.2 | 2.5 |

| 16 | 26 | 28 | 30.95 | 20.4 | 3 | 2.5 | 1.5 | 23 | 11.2 | 2.5 |

| 18 | 32 | 34 | 34.15 | 24.5 | 3 | 4 | 2 | 24 | 11.2 | 4 |

| 20 | 34 | 36 | 35.7 | 26.5 | 3 | 4 | 2.0. | 24 | 11.2 | 4 |

| 22 | 36 | 38 | 37.3 | 28.5 | 3 | 4 | 2 | 24 | 11.2 | 4 |

| 24 | 38 | 40 | 40.5 | 30.5 | 3 | 4 | 2 | 26.7 | 11.2 | 4 |

| 25 | 39 | 41 | 40.5 | 31.5 | 3 | 4 | 2 | 27 | 11.2 | 4 |

| 28 | 42 | 44 | 47.65 | 34.5 | 3 | 4 | 2 | 30 | 11.2 | 4 |

| 30 | 44 | 46 | 50.8 | 36.5 | 3 | 4 | 2 | 30.5 | 11.2 | 4 |

| 32 | 46 | 48 | 50.8 | 38.5 | 3 | 4 | 2 | 30.5 | 11.2 | 4 |

| 33 | 47 | 49 | 54 | 39.5 | 3 | 4 | 2 | 30.5 | 11.2 | 4 |

| 35 | 49 | 51 | 54 | 41.5 | 3 | 4 | 2 | 30.5 | 11.2 | 4 |

| 38 | 54 | 58 | 57.15 | 45 | 4 | 4 | 2 | 32 | 11.2 | 4 |

| 40 | 56 | 60 | 60.35 | 47 | 4 | 4 | 2 | 32 | 12.7 | 4 |

| 43 | 59 | 63 | 63.5 | 50 | 4 | 4 | 2 | 32 | 12.7 | 4 |

| 45 | 61 | 65 | 63.5 | 52 | 4 | 4 | 2 | 32 | 12.7 | 4 |

| 48 | 64 | 68 | 66.7 | 55 | 4 | 4 | 2 | 32 | 12.7 | 4 |

| 50 | 66 | 70 | 69.85 | 57 | 4 | 4 | 2.5 | 34 | 12.7 | 4 |

| 53 | 69 | 73 | 73.05 | 60 | 4 | 4 | 2.5 | 34 | 16 | 4 |

| 55 | 71 | 75 | 76.2 | 62 | 4 | 4 | 2.5 | 34 | 16 | 4 |

| 58 | 78 | 83 | - | 67.5 | 4 | 5.5 | 2.5 | 39 | 16 | 5.5 |

| 60 | 80 | 85 | 79.4 | 69.5 | 4 | 5.5 | 2.5 | 39 | 16 | 5.5 |

| 63 | 83 | 88 | - | 72.5 | 4 | 5.5 | 2.5 | 39 | 16 | 5.5 |

| 65 | 85 | 90 | 92.1 | 74.5 | 4 | 5.5 | 2.5 | 39 | 16 | 5.5 |

| 68 | 88 | 93 | 77.5 | 5.5 | 39 | 15.9 | 5.5 | |||

| 70 | 90 | 95 | 95.25 | 79.5 | 4 | 5.5 | 2.5 | 45.5 | 15.9 | 5.5 |

| 75 | 95 | 104 | 101.6 | 83.5 | 4 | 5.5 | 2.5 | 45.5 | 15.9 | 5.5 |

| 80 | 104 | 109 | 114.3 | 89.5 | 4 | 5.5 | 3 | 45 | 19.9 | 5.5 |

| 85 | 109 | 114 | 117.5 | 94.5 | 4 | 5.5 | 3 | 45 | 19.9 | 5.5 |

| 90 | 114 | 119 | 123.9 | 99.5 | 4 | 5.5 | 3 | 50 | 19.9 | 5.5 |

| 95 | 119 | 124 | 127 | 104.5 | 4 | 5.5 | 3 | 50 | 19.9 | 5.5 |

| 100 | 124 | 129 | 133.4 | 109.5 | 4 | 5.5 | 3 | 50 | 19.9 | 5.5 |

Materials of Construction

Crafted with high-quality materials, the Type 805 ensures durability and efficiency:

- Seal Faces: Carbon, Silicon Carbide (SiC), Tungsten Carbide (TC)

- Secondary Seals: FFKM, FKM, PTFE

- Metal Components: SS-316, Hastelloy-C, Inconel-718

Key Features

- Hydraulically Unbalanced Design: Engineered for optimal performance in low-pressure environments.

- Elastomer O-Ring: Provides a flexible and reliable sealing interface.

- Compact Design: Requires minimal axial and radial space for installation.

- Customizable Torque Drive Options: Available in Pin or Key Drive configurations.

- Minimal Components: Simplifies installation and maintenance.

- High RPM Compatibility: Ensures dependable performance at high rotational speeds.

- Rugged Construction: Built to endure challenging industrial conditions.

Why Choose Orbit Fluid Solution LLP?

At Orbit Fluid Solution LLP, we are committed to delivering cutting-edge sealing solutions tailored to meet the diverse demands of industrial operations. The Elastomer O Ring Unbalanced Seal Type: 805 combines innovative design with premium materials, ensuring superior performance, reduced downtime, and enhanced safety for your processes.