Description

Applications

The PTFE Wedge Unbalanced Seal Type: 806 is designed to meet the sealing requirements of diverse industries:

- Chemical Processing: Exceptional corrosion resistance ensures durability in aggressive chemical environments.

- Pharmaceutical: Hygienic sealing for processes requiring high precision and contamination control.

- Oil & Gas: Reliable performance in systems dealing with hydrocarbons and corrosive fluids.

- Mixers & Rotating Equipment: Provides a dependable solution for fluid handling in various configurations, including single, back-to-back, face-to-face, or tandem arrangements.

Industries Served

The Type 806 is suitable for numerous industrial sectors, including:

- Biofuels: Effective sealing for biofuel production systems.

- Chemical: Ideal for handling corrosive and volatile substances.

- Food & Beverage: Ensures safe and leak-proof sealing for food-grade applications.

- Mining & Minerals: Reliable in abrasive and slurry-laden environments.

- Oil & Gas: Delivers dependable sealing under varying pressures and temperatures.

- Power Generation: Ensures efficiency and safety in power plant operations.

- Pulp & Paper: Withstands the demands of slurry and high-viscosity media.

- Petrochemicals: Robust performance in challenging petrochemical applications.

- Pharmaceutical: Hygienic, reliable solutions for pharmaceutical manufacturing processes.

Operating Parameters

The Type 806 ensures optimal functionality within the following parameters:

- Shaft Diameter: 10 to 150 mm

- Pressure: Up to 10 Bars

- Temperature: -25°C to 220°C

- Speed: Up to 25 m/s

Materials of Construction

The Type 806 is crafted using premium materials to ensure durability and compatibility across applications:

- Seal Faces: Carbon, Silicon Carbide (SiC), Tungsten Carbide (TC)

- Secondary Seals: FFKM, FKM, PTFE

- Metal Components: SS-316, Hastelloy-C, Inconel-718

Key Features

- PTFE Wedge Design: Acts as the primary sealing element, offering exceptional chemical resistance.

- Hydraulically Unbalanced: Optimized for low-pressure applications.

- Compact Construction: Requires minimal axial and radial space, allowing easy integration.

- High RPM Compatibility: Performs reliably under high rotational speeds.

- Customizable Drive Options: Available in Pin or Key Drive versions for torque transmission flexibility.

- Versatile Configurations: Can be installed as single, back-to-back, face-to-face, or tandem seals.

- Rugged & Reliable: Designed for consistent performance in demanding industrial environments.

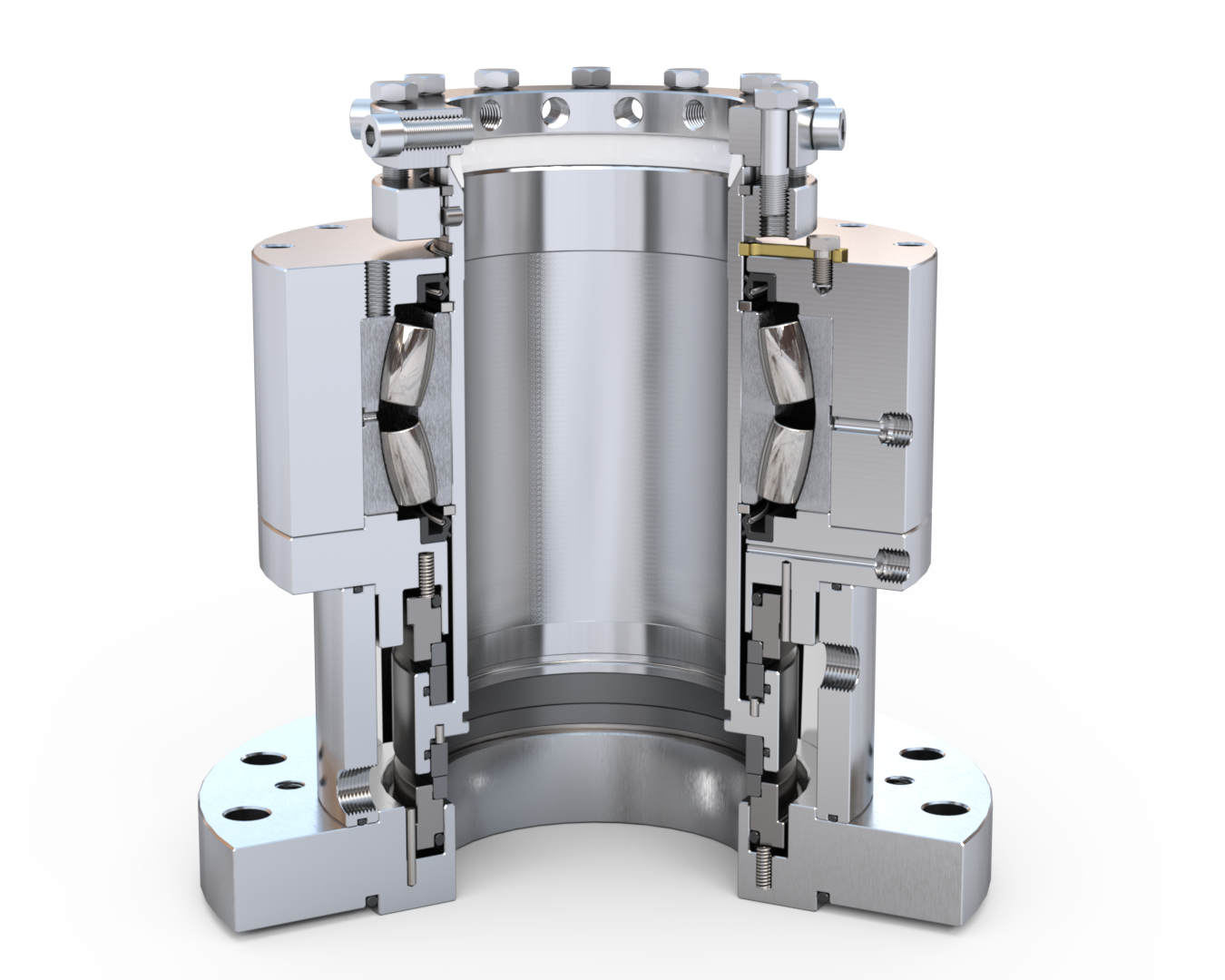

Seal Diagram

Dimensional Data

Dimensional Data Metrics| D1 | D2 | D3 | D4 | D5 | d1 | d2 | a | L1 | L2 | L3 |

|---|---|---|---|---|---|---|---|---|---|---|

| 14 | 24 | 26 | 24.6 | 18.4 | 3 | 2.5 | 1.5 | 23 | 11.2 | 2.5 |

| 16 | 26 | 28 | 30.95 | 20.4 | 3 | 2.5 | 1.5 | 23 | 11.2 | 2.5 |

| 18 | 32 | 34 | 34.15 | 24.5 | 3 | 4 | 2 | 24 | 11.2 | 4 |

| 20 | 34 | 36 | 35.7 | 26.5 | 3 | 4 | 2.0. | 24 | 11.2 | 4 |

| 22 | 36 | 38 | 37.3 | 28.5 | 3 | 4 | 2 | 24 | 11.2 | 4 |

| 24 | 38 | 40 | 40.5 | 30.5 | 3 | 4 | 2 | 26.7 | 11.2 | 4 |

| 25 | 39 | 41 | 40.5 | 31.5 | 3 | 4 | 2 | 27 | 11.2 | 4 |

| 28 | 42 | 44 | 47.65 | 34.5 | 3 | 4 | 2 | 30 | 11.2 | 4 |

| 30 | 44 | 46 | 50.8 | 36.5 | 3 | 4 | 2 | 30.5 | 11.2 | 4 |

| 32 | 46 | 48 | 50.8 | 38.5 | 3 | 4 | 2 | 30.5 | 11.2 | 4 |

| 33 | 47 | 49 | 54 | 39.5 | 3 | 4 | 2 | 30.5 | 11.2 | 4 |

| 35 | 49 | 51 | 54 | 41.5 | 3 | 4 | 2 | 30.5 | 11.2 | 4 |

| 38 | 54 | 58 | 57.15 | 45 | 4 | 4 | 2 | 32 | 11.2 | 4 |

| 40 | 56 | 60 | 60.35 | 47 | 4 | 4 | 2 | 32 | 12.7 | 4 |

| 43 | 59 | 63 | 63.5 | 50 | 4 | 4 | 2 | 32 | 12.7 | 4 |

| 45 | 61 | 65 | 63.5 | 52 | 4 | 4 | 2 | 32 | 12.7 | 4 |

| 48 | 64 | 68 | 66.7 | 55 | 4 | 4 | 2 | 32 | 12.7 | 4 |

| 50 | 66 | 70 | 69.85 | 57 | 4 | 4 | 2.5 | 34 | 12.7 | 4 |

| 53 | 69 | 73 | 73.05 | 60 | 4 | 4 | 2.5 | 34 | 16 | 4 |

| 55 | 71 | 75 | 76.2 | 62 | 4 | 4 | 2.5 | 34 | 16 | 4 |

| 58 | 78 | 83 | - | 67.5 | 4 | 5.5 | 2.5 | 39 | 16 | 5.5 |

| 60 | 80 | 85 | 79.4 | 69.5 | 4 | 5.5 | 2.5 | 39 | 16 | 5.5 |

| 63 | 83 | 88 | - | 72.5 | 4 | 5.5 | 2.5 | 39 | 16 | 5.5 |

| 65 | 85 | 90 | 92.1 | 74.5 | 4 | 5.5 | 2.5 | 39 | 16 | 5.5 |

| 68 | 88 | 93 | 77.5 | 5.5 | 39 | 15.9 | 5.5 | |||

| 70 | 90 | 95 | 95.25 | 79.5 | 4 | 5.5 | 2.5 | 45.5 | 15.9 | 5.5 |

| 75 | 95 | 104 | 101.6 | 83.5 | 4 | 5.5 | 2.5 | 45.5 | 15.9 | 5.5 |

| 80 | 104 | 109 | 114.3 | 89.5 | 4 | 5.5 | 3 | 45 | 19.9 | 5.5 |

| 85 | 109 | 114 | 117.5 | 94.5 | 4 | 5.5 | 3 | 45 | 19.9 | 5.5 |

| 90 | 114 | 119 | 123.9 | 99.5 | 4 | 5.5 | 3 | 50 | 19.9 | 5.5 |

| 95 | 119 | 124 | 127 | 104.5 | 4 | 5.5 | 3 | 50 | 19.9 | 5.5 |

| 100 | 124 | 129 | 133.4 | 109.5 | 4 | 5.5 | 3 | 50 | 19.9 | 5.5 |

Important Notes

- Ensure compatibility of materials with the operating media for maximum performance.

- Follow the recommended installation guidelines to prevent operational issues.

- For specific application requirements, consult Orbit Industries’ technical support team for tailored solutions.

Why Choose Orbit Fluid Solution LLP?

With over three decades of expertise, Orbit Fluid Solution LLP is a global leader in mechanical sealing solutions. The PTFE Wedge Unbalanced Seal Type: 806 exemplifies our commitment to delivering innovative, reliable, and high-quality products tailored to industrial needs.

Trust Orbit Fluid Solution LLP for sealing solutions that enhance productivity, minimize downtime, and ensure safety across your operations.