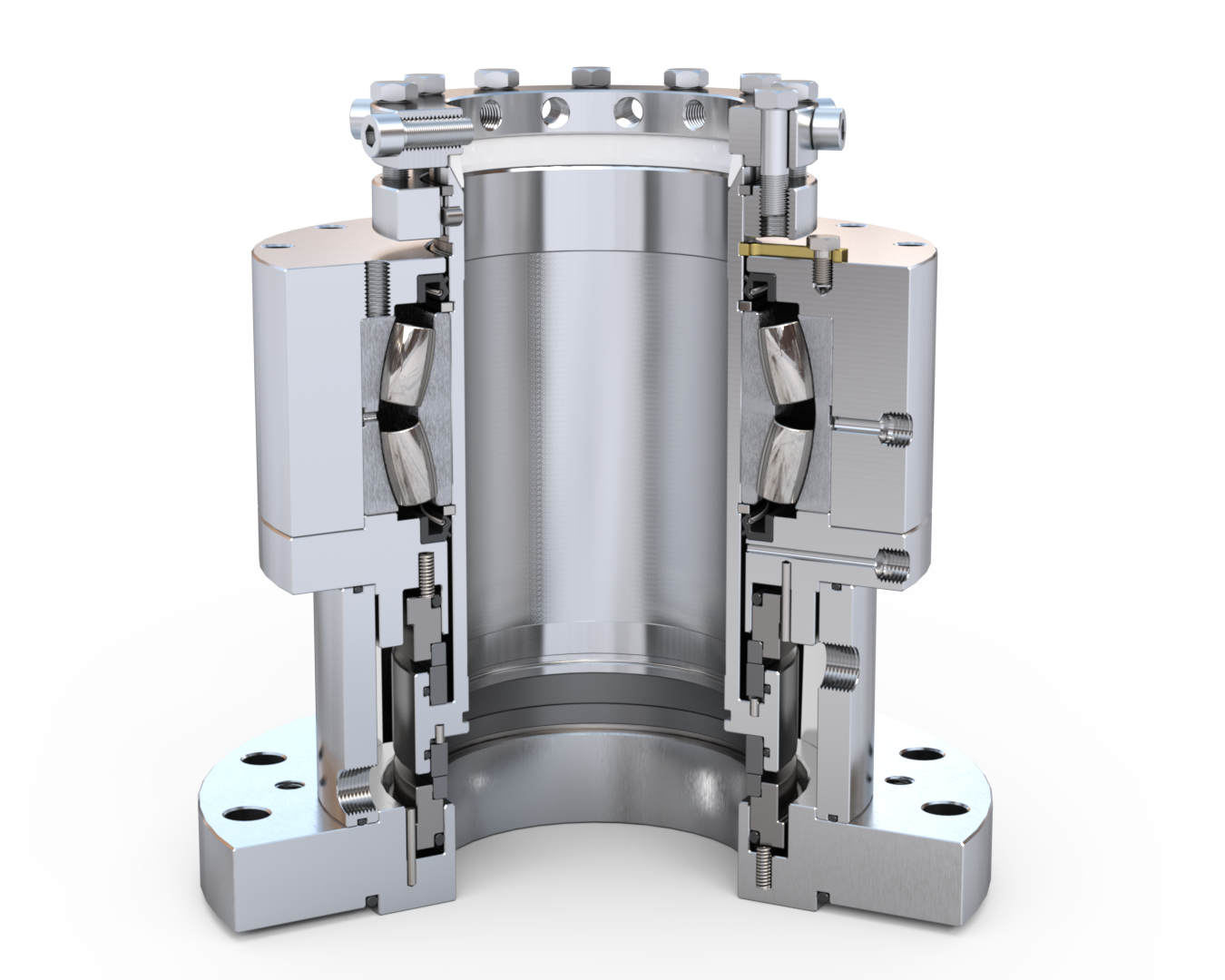

Description

Applications

The Single Coil Unbalanced O Ring Seal Type: 706 is optimized for challenging conditions, offering reliable performance in:

- Abrasive Media: Ideal for sealing applications involving slurries, sludge, and fluids containing abrasive particles.

- Viscous Fluids: Capable of handling polymerizing fluids, thick syrups, and other high-viscosity liquids with ease.

- High-Sealing Force Requirements: Generates a higher sealing force due to its unbalanced design, ensuring effective sealing in processes involving solid particles or viscous media.

- Pumps and Reactors: Perfect for single and double seal arrangements in industrial pumps and reactor systems, providing consistent and reliable operation.

- Chemical and Corrosive Environments: With corrosion-resistant materials, this seal is well-suited for chemical processing applications involving aggressive substances.

Industries Served

The Single Coil Unbalanced O Ring Seal Type: 706 is specifically designed to meet the diverse needs of the following industries:

- Automotive: Reliable sealing for automotive production processes, including handling abrasive and high-viscosity fluids.

- Biofuels: Robust performance in biofuel production systems, ensuring efficiency in managing slurries and corrosive substances.

- Food & Beverage: Ideal for hygienic and efficient operations in food and beverage processing, especially when managing thick syrups or similar fluids.

- Water & Waste Water: Ensures dependable sealing in water treatment plants and wastewater systems dealing with sludge and abrasive particles.

Operating Parameters

The Single Coil Unbalanced O Ring Seal Type: 706 is engineered to deliver exceptional performance under the following operational conditions:

- Shaft Diameter: 24 to 150 mm

- Pressure: Up to 10 Bars

- Temperature Range: -20°C to 120°C

- Speed: Up to 20 m/s

Materials of Construction

The seal is built using premium-quality materials to ensure durability and resistance to wear and corrosion:

- Seal Faces: Carbon/Silicon Carbide/Tungsten Carbide (Customizable based on application)

- Secondary Seals: FFKM/FKM/PTFE

- Metal Components: SS-316/Hastelloy-C/Inconel-718

Key Features

- Easy Installation: Streamlined design minimizes installation effort and downtime.

- Compact Design: Requires minimal axial and radial space, making it ideal for systems with tight tolerances.

- Versatile Application: Suitable for viscous media and abrasive environments.

- Rugged and Reliable: Engineered for durability and consistent performance under demanding conditions.

- Minimal Components: Simplified construction reduces maintenance requirements and operational complexity.

Advantages of the Single Coil Unbalanced Design

The unbalanced configuration of the Type 706 provides enhanced sealing force, making it an excellent choice for managing fluids with solid particles or high viscosity. Its robust design ensures long-lasting performance even in harsh environments, reducing downtime and maintenance costs.

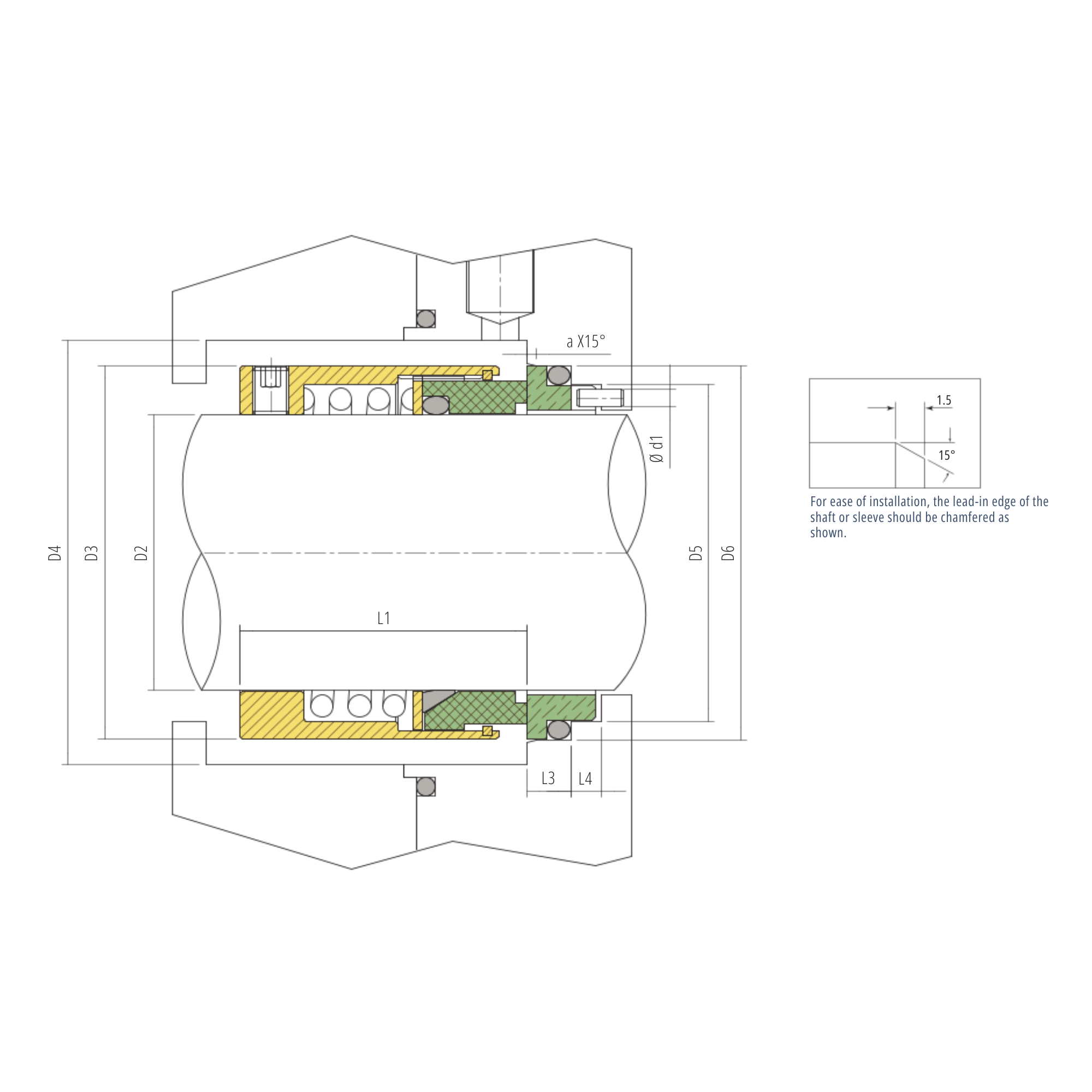

Technical Dimensions

Below is the table of dimensions for the Single Coil Unbalanced O Ring Seal Type: 706:

Seal Diagram

Dimensional Data Metrics

| D2 | D3 | D4 | D5 | D6 | d1 | L1 | a | L3 | L4 |

|---|---|---|---|---|---|---|---|---|---|

| 14 | 24 | 26 | 21 | 25 | 3 | 31 | 1.5 | 4 | 8.5 |

| 16 | 26 | 28 | 23 | 27 | 3 | 31 | 1.5 | 4 | 8.5 |

| 18 | 32 | 34 | 27 | 33 | 3 | 34.5 | 2 | 5 | 9 |

| 20 | 34 | 36 | 29 | 35 | 3 | 34.5 | 2 | 5 | 9 |

| 22 | 36 | 38 | 31 | 37 | 3 | 34.5 | 2 | 5 | 9 |

| 24 | 38 | 40 | 33 | 39 | 3 | 39.5 | 2 | 5 | 9 |

| 25 | 39 | 41 | 34 | 40 | 3 | 39.5 | 2 | 5 | 9 |

| 28 | 42 | 44 | 37 | 43 | 3 | 39.5 | 2 | 5 | 9 |

| 30 | 44 | 46 | 39 | 45 | 3 | 39.5 | 2 | 5 | 9 |

| 32 | 46 | 48 | 42 | 48 | 3 | 44.5 | 2 | 5 | 9 |

| 33 | 47 | 49 | 42 | 48 | 3 | 44.5 | 2 | 5 | 9 |

| 35 | 49 | 51 | 44 | 50 | 3 | 44.5 | 2 | 5 | 9 |

| 38 | 54 | 58 | 49 | 56 | 4 | 43.5 | 2 | 6 | 9 |

| 40 | 56 | 60 | 51 | 58 | 4 | 43.5 | 2 | 6 | 9 |

| 43 | 59 | 63 | 54 | 61 | 4 | 48.5 | 2 | 6 | 9 |

| 45 | 61 | 65 | 56 | 63 | 4 | 48.5 | 2 | 6 | 9 |

| 48 | 64 | 68 | 59 | 66 | 4 | 48.5 | 2 | 6 | 9 |

| 50 | 66 | 70 | 62 | 70 | 4 | 46.5 | 2.5 | 6 | 9 |

| 53 | 69 | 73 | 65 | 73 | 4 | 56.5 | 2.5 | 6 | 9 |

| 55 | 71 | 75 | 67 | 75 | 4 | 56.5 | 2.5 | 6 | 9 |

| 58 | 78 | 83 | 70 | 78 | 4 | 56.5 | 2.5 | 6 | 9 |

| 60 | 80 | 85 | 72 | 80 | 4 | 56.5 | 2.5 | 6 | 9 |

| 63 | 83 | 88 | 75 | 83 | 4 | 56.5 | 2.5 | 6 | 9 |

| 65 | 85 | 90 | 77 | 85 | 4 | 66.5 | 2.5 | 6 | 9 |

| 68 | 88 | 93 | 81 | 90 | 4 | 64.5 | 2.5 | 7 | 9 |

| 70 | 90 | 95 | 83 | 92 | 4 | 64.5 | 2.5 | 7 | 9 |

| 75 | 99 | 104 | 88 | 97 | 4 | 64.5 | 2.5 | 7 | 9 |

| 80 | 104 | 109 | 95 | 105 | 4 | 74 | 3 | 7 | 9 |

| 85 | 109 | 114 | 100 | 110 | 4 | 74 | 3 | 7 | 9 |

| 90 | 114 | 119 | 105 | 115 | 4 | 74 | 3 | 7 | 9 |

| 95 | 119 | 124 | 110 | 120 | 4 | 74 | 3 | 7 | 9 |

| 100 | 124 | 129 | 115 | 125 | 4 | 74 | 3 | 7 | 9 |

Contact Us for Customization

At Orbit Fluid Solution LLP, we understand that every application is unique. Our design team is available to provide customized sealing solutions tailored to your specific operational requirements.

If your process involves potentially hazardous or dangerous conditions, we strongly recommend consulting with an Orbit Fluid Solution LLP representative to ensure product suitability and safe operation. Your safety and operational efficiency are our top priorities.

Optimize reliability with our Single Coil Unbalanced O Ring Seal. Contact us now for superior sealing solutions!