Description

Applications

The Type 902B is meticulously engineered for industries and processes where reliability and efficiency are paramount. Key application areas include:

- Slurry Handling: Ensures exceptional performance in applications with abrasive slurries, preventing spring damage by isolating the springs from the media.

- High-Viscosity Fluids: Excels in handling polymerizing, viscous, and solid-laden fluids commonly encountered in pumps and reactors.

- Critical Component Protection: Dynamic O-ring loaded on the drive collar safeguards the pump sleeve and shaft, enhancing operational lifespan and reducing maintenance costs.

- Aggressive Media: Designed for environments with corrosive, abrasive, or challenging media, ensuring consistent sealing performance.

Industries Served

The Wave Spring Self Balanced O Ring Seal Type: 902B is an ideal choice for a wide range of industries:

- Biofuels: Reliable sealing solutions for biofuel production systems involving abrasive and viscous media.

- Chemical: Engineered for high-performance sealing in chemical processing involving corrosive and polymerizing substances.

- Food & Beverage: Suitable for hygienic processing of high-viscosity liquids and syrups in food and beverage manufacturing.

- Mining & Minerals: Designed for abrasive slurry handling in mining operations and mineral processing.

- Oil & Gas: Robust performance in upstream and downstream oil and gas applications involving challenging fluids.

- Power Generation: Effective sealing solutions for power generation plants handling diverse media.

- Pulp & Paper: Ensures smooth operation in pulp and paper manufacturing processes with slurries and high-viscosity materials.

- Petrochemicals: Durable and efficient for petrochemical processing involving abrasive and corrosive fluids.

- Pharmaceutical: Hygienic and reliable sealing for pharmaceutical processes requiring high efficiency and clean operations.

Operating Parameters

The Type 902B delivers superior performance under the following operational conditions:

- Shaft Diameter: 18 to 120 mm

- Pressure: Vacuum to 20 Bars

- Temperature: -20°C to 180°C

- Speed: Up to 25 m/s

Materials of Construction

To ensure durability and compatibility with various applications, the Type 902B is manufactured using high-quality materials:

- Seal Faces: Carbon, Silicon Carbide (SiC), Tungsten Carbide (TC), Aluminum Oxide (AlO2)

- Secondary Seals: NBR, FKM, FFKM, EPDM

- Metal Components: SS-316, SS-304, Hastelloy-C246, Inconel-718

Key Features

- Wave Spring Design: Provides reliable performance in highly viscous and abrasive media.

- Isolated Springs: Prevents product contact with springs, ensuring enhanced durability and operational longevity.

- Self-Balanced Configuration: Eliminates the need for balancing steps on shafts or sleeves, simplifying installation.

- Dynamic O-Ring Protection: Protects pump sleeves and shafts, reducing wear and tear over time.

- Compact Design: Requires minimal axial and radial space, making it suitable for systems with limited room.

- Rugged and Reliable: Engineered for consistent performance in challenging environments.

- Easy Installation: Designed for quick and hassle-free installation, minimizing downtime.

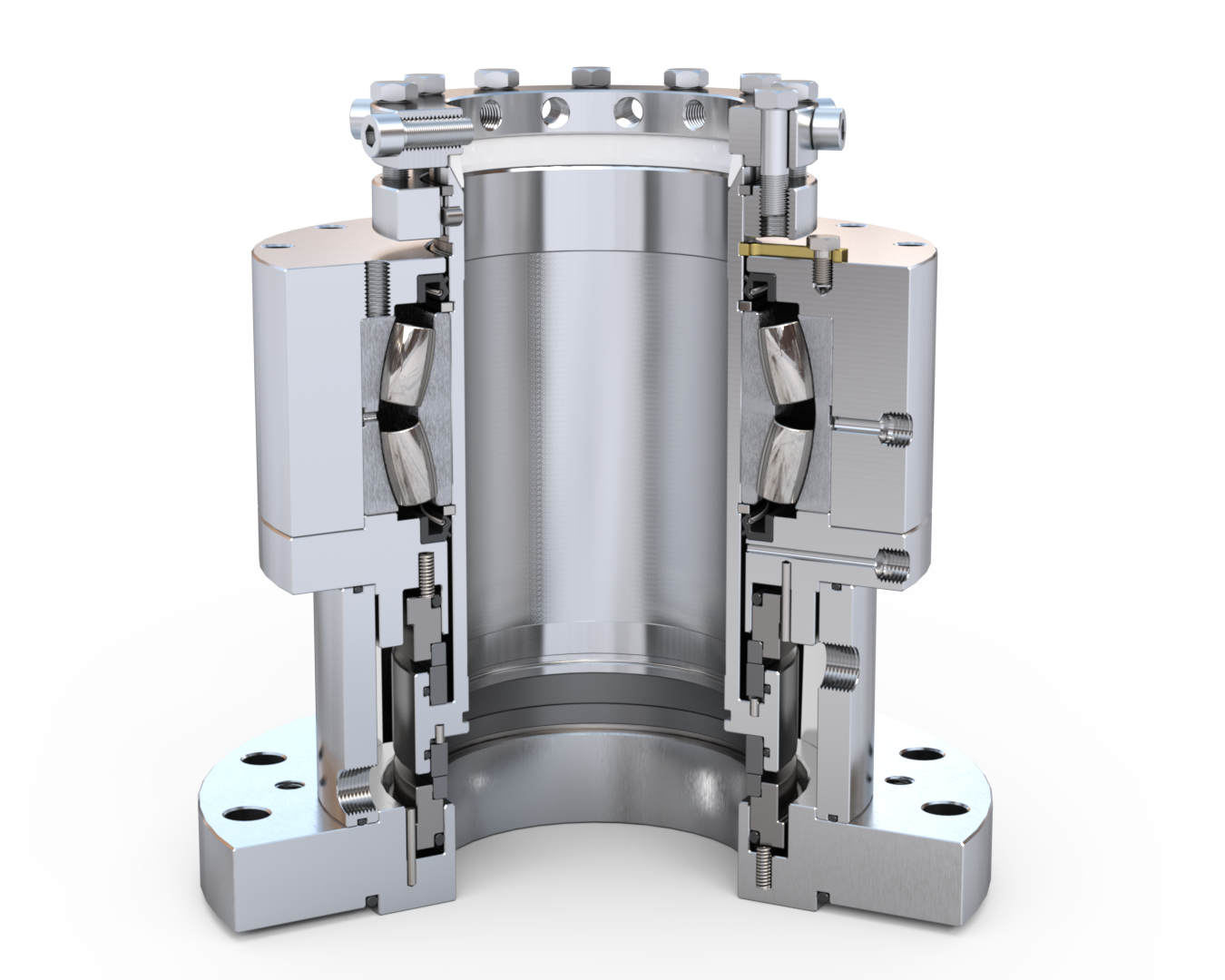

Seal Diagram

Dimensional Data

Dimensional Data Metrics| D1 | D2 | D3 | D4 | D5 | D6 | L1 | L2 | L3 | L4 |

|---|---|---|---|---|---|---|---|---|---|

| 18 | 32 | 26 | 27 | 33 | 3 | 30.5 | 15 | 37.5 | 9 |

| 20 | 34 | 28 | 29 | 35 | 3 | 30.5 | 15 | 37.5 | 9 |

| 22 | 36 | 30 | 31 | 37 | 3 | 30.5 | 15 | 37.5 | 9 |

| 24 | 38 | 32.5 | 33 | 39 | 3 | 33 | 15 | 40 | 9 |

| 25 | 39 | 33.5 | 34 | 40 | 3 | 33 | 15 | 40 | 9 |

| 28 | 42 | 36.5 | 37 | 43 | 3 | 35.5 | 15 | 42.5 | 9 |

| 30 | 44 | 38.5 | 39 | 45 | 3 | 35.5 | 15 | 42.5 | 9 |

| 32 | 47 | 41.5 | 42 | 48 | 3 | 35.5 | 15 | 42.5 | 9 |

| 33 | 47 | 41.5 | 42 | 48 | 3 | 35.5 | 15 | 42.5 | 9 |

| 35 | 49 | 43.5 | 44 | 50 | 3 | 35.5 | 15 | 42.5 | 9 |

| 38 | 54 | 47.5 | 49 | 56 | 4 | 37 | 16 | 45 | 9 |

| 40 | 56 | 49.5 | 51 | 58 | 4 | 37 | 16 | 45 | 9 |

| 43 | 59 | 52.5 | 54 | 61 | 4 | 37 | 16 | 45 | 9 |

| 45 | 61 | 54.5 | 56 | 63 | 4 | 37 | 16 | 45 | 9 |

| 48 | 64 | 57.5 | 59 | 66 | 4 | 37 | 16 | 45 | 9 |

| 50 | 66 | 59.5 | 62 | 70 | 4 | 38 | 17 | 47.5 | 9 |

| 53 | 69 | 62.5 | 65 | 73 | 4 | 38 | 17 | 47.5 | 9 |

| 55 | 71 | 64.5 | 67 | 75 | 4 | 38 | 17 | 47.5 | 9 |

| 58 | 78 | 68.5 | 70 | 78 | 4 | 42 | 18 | 52.5 | 9 |

| 60 | 80 | 70.5 | 72 | 80 | 4 | 42 | 18 | 52.5 | 9 |

| 63 | 83 | 73.5 | 75 | 83 | 4 | 42 | 18 | 52.5 | 9 |

| 65 | 85 | 75.5 | 77 | 85 | 4 | 42 | 18 | 52.5 | 9 |

| 68 | 88 | 78.5 | 81 | 90 | 4 | 41.5 | 18.5 | 52.5 | 9 |

| 70 | 90 | 80.5 | 83 | 92 | 4 | 48.5 | 19 | 60 | 9 |

| 75 | 99 | 89 | 88 | 97 | 4 | 48.5 | 19 | 60 | 9 |

| 80 | 104 | 94 | 95 | 105 | 4 | 48.5 | 19 | 60 | 9 |

| 85 | 109 | 99 | 100 | 110 | 4 | 48.5 | 19 | 60 | 9 |

| 90 | 114 | 104 | 105 | 115 | 4 | 52 | 20.5 | 65 | 9 |

| 95 | 119 | 109 | 110 | 120 | 4 | 52 | 20.5 | 65 | 9 |

| 100 | 124 | 114 | 115 | 125 | 4 | 52 | 20.5 | 65 | 9 |

Important Notes

- Ensure compatibility of materials with the media before installation.

- Consult Orbit Fluid Solution LLP technical team for customized solutions or assistance with complex applications.

- Always follow installation guidelines to ensure optimal performance and longevity of the seal.

Why Choose Orbit Fluid Solution LLP ?

At Orbit Fluid Solution LLP, we are dedicated to providing innovative sealing solutions that meet the diverse needs of global industries. The Wave Spring Self Balanced O Ring Seal Type: 902B is a testament to our commitment to engineering excellence, precision, and customer satisfaction.

With decades of experience, cutting-edge technology, and a focus on quality, we deliver products that drive efficiency, reduce downtime, and enhance operational performance.